Whoops

Editor's Note: We had a bit of a computer malfunction the first time sending this, so it's going out again. You may receive it twice, giving you more bang for your buck!—JP

New Tech at Cultivate

A couple of new technologies have caught my eye from Cultivate’25, and they’re well worth a look, not only to see what’s new on the market, but also to understand their broader impact on the industry. Some of these innovations are built on techniques and technologies that, until about a decade ago, hadn’t seen widespread adoption. Now, they’re gaining serious traction, and changing the way we think about production and efficiency in horticulture.

Climaflow from Svensson

As Plant Empowerment becomes a more widespread growing philosophy, balancing plant inputs and outputs has become a challenge, not just for growers, but also for the engineers designing greenhouses to support such precise control. One of the trickiest areas has been managing the relationship between temperature, humidity and radiation to and from the crop. Add in regulations around light pollution, and nighttime greenhouse management becomes even more complex. Growers are often caught between the need to circulate air and the need to keep energy curtains closed.

This leads to a central question: how do you circulate air through a closed screen? Not just a gentle breeze, but enough air movement to matter?

Climaflow offers a solution. Think of it as a high-efficiency VAF (vertical airflow) system paired with a slim duct that fits between closed curtains, allowing for effective air circulation even when the screen is sealed. This setup enables growers to maintain uniform airflow across the greenhouse while keeping the top screened off, achieving daytime shading and nighttime protection against radiative heat loss to the cold glass above.

With Climaflow, growers gain a new level of environmental control, supporting Plant Empowerment strategies without sacrificing energy efficiency or airflow.

Check out the product and watch the informational video here.

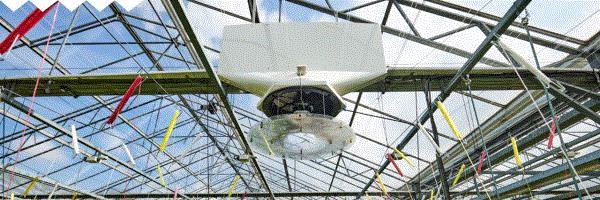

Climaflow System from Svensson

ReduCompact Coating

I’ve spent much of my research career studying how different wavelengths affect plant growth, and one of the simplest and most well-known light responses is how the red:blue ratio influences plant compaction. Generally, the higher the blue light, the more compact the plant grows. (That is, unless you go 100% blue LEDs, then paradoxically plants stretch like crazy.)

In greenhouses, though, the sheer intensity of sunlight can make it difficult for supplemental lighting to deliver noticeable spectral effects. ReduSystems has taken advantage of this challenge with the development of ReduCompact, a seasonal glass coating that filters out portions of red and green light, resulting in a relatively higher blue spectrum reaching the crop.

ReduCompact functions much like traditional whitewash, commonly used to reduce overall light and solar heat gain during high-light seasons. But instead of simply cutting intensity, it selectively alters the spectrum, making it a potentially powerful tool for growers aiming to keep plants shorter and more compact during peak sunlight months.

However, timing is everything. ReduCompact should only be applied when reducing total sunlight is also beneficial, typically in late spring and summer. Using it in fall or winter, when light is already limited, is not recommended and could negatively affect crop growth.

Learn more about ReduCompact and its applications here.

Mobile Gully Systems

Hort Americas recently announced a new partnership with Mobile Gully Systems (MGS), a company specializing in automated NFT (Nutrient Film Technique) channel systems. As I’ve written about before, we’re in the midst of a boom in automated NFT technology, and MGS offers a compelling solution, now paired with a trusted North American distributor.

MGS systems are designed not only to move plants throughout the greenhouse, from propagation to harvest zones, but also to adjust gully spacing dynamically. This ensures optimal plant density and space usage at each stage of the crop cycle, which is critical for maximizing yield and efficiency.

The system is flexible: it can accommodate manual planting and harvesting, but it’s also fully compatible with automation-heavy setups that use machine transplanting and harvesting. With roots in Belgium, MGS has brought its proven tech to operations around the world, and this new partnership with Hort Americas makes that technology more accessible to growers across North America. Local support for installation, service and operational guidance will help ensure these systems are integrated smoothly and effectively.

You can read more in the official press release linked here.

Koppert Cress Invests in Skytree DAC

When it comes to innovation, Koppert Cress has built a reputation for offering some of the most unusual and astonishing crops on the market. From familiar edible flowers like pansies and nasturtiums to more obscure culinary curiosities like majii leaves and blinq blossoms, their collection catalog is worth skimming through.

Now, in addition to their inventive crop lineup, Koppert Cress is investing in a cutting-edge green technology aimed at reducing their environmental footprint: carbon dioxide supplementation through Skytree’s Direct Air Capture (DAC) systems.

DAC is an emerging, commercially viable technology that works by extracting carbon dioxide directly from the atmosphere and injecting it into the greenhouse environment. This gives growers like Koppert Cress the CO₂ enrichment they need for optimal plant growth—without relying on fossil fuel–derived CO₂. It’s a sustainable solution that aligns with the company’s forward-thinking approach to production and environmental stewardship.

Skytree, the company behind this technology, brings over a decade of experience in DAC innovation and has operations in the Netherlands, Canada and the United States. Their systems offer growers a new way to boost yields while reducing dependency on industrial CO₂ supply chains.

To learn more, follow the links to the official press release and visit Skytree’s website for details on how their technology supports greenhouse CO₂ supplementation.

Oasis Grower Solutions Website

A new website has been launched for a company with over 50 years of experience in horticulture: Oasis Grower Solution. The site is packed with fresh resources and features an intuitive design that makes it easy for growers to navigate and quickly find the products and information they need.

“We really wanted to create a site that serves as a knowledge hub for people in the horticulture and agriculture industries and helps fulfill our purpose to provide innovative, real-world solutions for their problems. I’m very proud that this new website is both beautiful and functional, and achieves our goal of supporting and serving growers, farmers and researchers worldwide in their work.” Director of Global Grower Operations & Research Vijay Rapaka, Ph.D said about the site.

After spending some time exploring the site myself, I was impressed by how easily I could locate specific products, view detailed specs and dimensions, and find guidance on how best to apply them for the crops I’m working with. It’s a slick new site that clearly reflects the company’s ongoing commitment to innovation and grower success.

Follow the link to check it out for yourself.

A comparison of square and round Oasis plugs.

Little Leaf Expansion

One of the fastest growing leafy greens producers in the country, Little Leaf Farms, has announced a major expansion that will significantly increase its production capacity. The company is planning to build a massive new facility in Manchester, Tennessee. The campus itself spans 215 acres, and of that space, 40 acres will be covered with glass, with room to double the greenhouse footprint to 80 acres as demand grows.

Construction will begin soon, with the opening expected in the fall of 2026. This marks a bold move for the company as it scales its operations to meet growing consumer demand for fresh, locally grown lettuce year-round.

According to Nielsen, a global marketing research and data analytics firm, Little Leaf Farms already holds over 50% of the indoor lettuce market in the United States. With the addition of this massive Tennessee facility, the company is positioned to strengthen its lead and supply even more of the nation’s indoor-grown greens. The location also helps Little Leaf Farms reach more regions efficiently, improving distribution and freshness for customers across the South and Midwest.

To learn more about Little Leaf Farms, their sustainable growing practices, and this latest expansion, visit their website or check out the official press release.

Dr. Jake Holley

Editor-at-Large

Inside Grower

This email received by 34,351 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.