Update from Jake’s Greenhouse

I typically avoid self-promotion, but when cool things happen in my greenhouse, I can’t help but share. We’ve started a trial to examine the effects of peroxides in our hydroponic systems. While peroxide use in hydroponics isn’t new, I’m excited to explore some unexpected benefits and give you a fresh perspective on a handful of things to improve water treatment. Today’s theme is using additives and treatments that don’t generate toxic residues or other nasty chemicals. Hopefully, today’s newsletter sparks the same excitement for you as it did for me while writing it.

My research interests focus on organically derived nutrients, microbes, biostimulants and regenerative agriculture. One of the biggest mysteries in this field is why aquaponics is an effective way to grow plants, despite the almost comical differences in water chemistry compared to traditional hydroponics. For example, we run our conventional systems at 150 ppm nitrate and a pH of 5.8, while our aquaponic system runs around 40 ppm nitrate with a pH of 6.8. Despite these differences, we don’t see a dramatic difference in growth (though aquaponics generally yields a bit less).

To start, I decided to explore what happens when you significantly reduce the organic compounds and microbes in both conventional and decoupled aquaponic systems by adding Sanidate 5.0 at 0.13 ml/l. Sanidate contains both hydrogen peroxide and peracetic acid, which attack organic molecules.

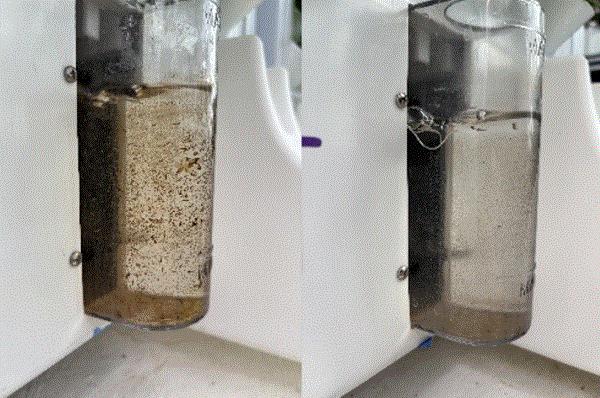

While results are still two weeks away, check out the difference in water clarity! The two pictures below are from the conventional system, although the decoupled aquaponic system looks much the same. The difference in water clarity, along with the overall similarity in plant growth, suggests that this treatment could be worthwhile for keeping systems clean. If you’re spending a lot of time scrubbing algae or clearing fouling from lines and emitters, it may be worth considering.

Vertical hydroponic system growing arugula, lettuce and spinach. The two walls on the left are fertilized with aquaponics water, while the right is Jack's 5-12-26 with Cal Nit. The systems on the left and right ends have been treated with Sanidate.

A view of the two conventional reservoirs. The right reservoir has been treated with Sanidate.

Plasma-Activated Water

Let’s talk about water treatment; specifically, how we can generate reactive species like peroxides on-site. In CEA, clean water is essential for everything from irrigation and pad walls to sanitation and postharvest washing. Traditionally, we’ve relied on bottled peroxide products, but new tech like Plasma-Activated Water might offer a cheaper, more efficient way to create those reactive compounds directly in your system.

Plasma-Activated Water is water that has been treated with an electrical current to produce a variety of reactive species. Specifically, our friend hydrogen peroxide, as well as ozone, nitrite, nitrate (yes the fertilizer), and a handful of other short-lived species like hydroxyl and superoxide. This water can be applied in a variety of ways, from irrigation, to pad walls, to postharvest washing.

Much like other technologies, the upfront cost of plasma systems is high, but the operational costs can be much lower than buying peroxide products. With peroxide products generally being more expensive to less desirable alternatives, like bleach, onsite generation may help to alleviate costs in the long run if you want to use these more ecofriendly and non-residual products. To learn more, check out this TED talk or visit HydroPlasma, a commercial Plasma-Activated Water system producer.

Improving Water Flow Using Physics

I recently learned the word exaptation from CSU’s Director of Ag Innovation, Jordan Lambert. Originally a biological term, it refers to a trait that evolved for one purpose but later serves a different function. A classic example is bird feathers, initially thought to be useful for temperature regulation, later essential for flight. I love this concept because it applies just as well to technology. In agriculture, we’re often borrowing tools or ideas from other industries and repurposing them. A great example is the recent crossover of water flow technologies from mining and aerospace into controlled environment agriculture.

GS Vortex Systems–Converting Laminar to Vortex Flow

The mining industry uses water for all sorts of tasks, including transporting ores from extraction sites to processing areas. The pipes that carry this slurry of minerals and water often clog, as minerals stick to the sidewalls, reducing flow and increasing the energy needed to pump a given volume. In a typical pumping system, water moves via laminar flow. However, adding a passive nozzle can redirect water into a vortex flow pattern, which reduces buildup and moves water more efficiently with less friction against the pipe walls. This technology has already been successfully applied to field center-pivot irrigators and may soon find its way into greenhouses. Click here to learn more.

SKW System–Electromagnetic Pulses

No one wants clogged pipes, especially in systems as sensitive as those feeding aircraft lavatories. Technology originally developed to keep airplane plumbing running smoothly is now being trialed in greenhouses. Using electromagnetism and the Lorentz force, this system alters water flow to prevent buildup, keeping dissolved ions and particulates from sticking to pipes. When I first entered the field of horticulture, the word uniformity was constantly emphasized, and consistent watering is key to maintaining uniformity in your crop. This old tech that’s new to the greenhouse world can keep your irrigation system flowing more evenly over your crops. Here’s a link to SKW's site.

Cavitation to Clean Water

The last water treatment technology I’ll mention, chemical-free and based on one of my favorite physical phenomena, is cavitation. Cavitation occurs when a vapor-filled bubble collapses, creating a powerful shockwave. This effect appears in all sorts of places: from the design of submarine propellers (which aim to reduce cavitation), to shattering the bottom of a glass bottle by hitting the top, and even contributing to the deadly strike of the mantis shrimp. When applied to industrial agricultural systems, cavitation can serve as a disinfectant by destroying algae and other biofilms.

Ultramins is a producer of cavitation products that use ultrasonic transmitters to generate cavitation bubbles capable of effectively destroying microorganisms. Compared to some of the other technologies I’ve mentioned, this method’s disinfecting effect is purely physical. That means, unlike peroxides, the risk of damaging plants is low to non-existent, especially since cavitation can be confined to areas away from plant roots.

Pad Wall Activation Season

It’s that time of year to start up the evaporative cooling systems in your greenhouses. From hard water, algae and the composition of your pads themselves, here’s some tips and new technology that can help maintain your padwalls.

Like peanut butter, there’s two flavors of things that build up on pad walls, crunchy and smooth. The crunchy stuff is hard water buildup, usually in the form of calcium and magnesium carbonate. These salts are naturally occurring in water and as the water evaporates, it’s left behind. The smooth flavor is algae and sometime mold growth.

To avoid hard water buildup, there’s a handful of things you can do. Starting with water that has less salts in it will help. Adding a water softener will replace the carbonate minerals with sodium chloride, which greatly reduces buildup. Adding a Reverse Osmosis system (R.O. system) will bring down dissolved salts in general (R.O. works better with a softener step as well). If you’re just using tap water, a periodic water change every few weeks also will help. Even if you start with R.O. water, as it evaporates the minerals will build up. So the occasional flush will help. Lastly, there’s various products containing acidic compounds that will inhibit these buildups from forming.

For the microbes, a few practices can really help. First, setting your greenhouse controller to stop the flow of the pump at the end of the day while maintaining air flow will dry your pads. Just like plants, completely drying out the substrate will inhibit algae growth. Second, some of the same products that help reduce hard water buildup can reduce algae buildup, like peroxides!

Lastly, the materials of the pads themselves are being innovated. The tried and tested material is a resin-coated cardboard material. If you do a great job taking care of these, they can last you a few seasons. New on the market are plastic-based pads, often with a honeycomb structure. These pads boast longer lifespans, the ability to be pressure washed and better airflow characteristics. I haven’t seen these used in a greenhouse in person, so if you have those, send me a note,—I’d love to hear if they’re worth trying out!

Educational Opportunity Update

Water, Nutrients, and Substrates Webinar Series

The University of Arkansas Root Alliance in partnership with UConn and University of Florida is offering a webinar series discussing root health and growth. Each webinar is offered at the very affordable price of $20 and the series starts Monday, June 9th.

For more information and to register, check out the link below:

Water, Nutrients, and Substrates -- Innovating Root Zone Solutions for Controlled Environment Horticulture - Formstack

Registration Now Open For 2025 OHCEAC Annual Conference

The Ohio State University’s annual conference, titled “Advancement of High Quality Transplant Production Technologies under Controlled Environments” is officially opened to registration. The conference will be held on July 16 both in person and online. The conference is organized by Dr. Cheri Kubota and Carly Becker and will feature five keynote speakers discussing all aspects of plant propagation and growing plugs. In person attendees will be given lunch, tours of the CEARC facilities and a networking social. Check out their website to learn more and sign up!

The Ohio State University's CEARC Facility

Tariffs

Here in my home state of Colorado, we commonly reference the saying “if you don’t like the weather here, wait 30 minutes.” This was especially true this week as it’s been 70F outside all week, snowed six inches yesterday and it’s all melted today.

I’ve been avoiding writing about tariffs as the policies are changing as fast as Colorado weather. Nevertheless, the more information we have, the better. To keep up to date with the newest policies, check out this link from the International Fresh Produce Association.

Have a great week and happy growing!

Dr. Jake Holley

Editor-at-Large

Inside Grower

This email received by 34,143 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.