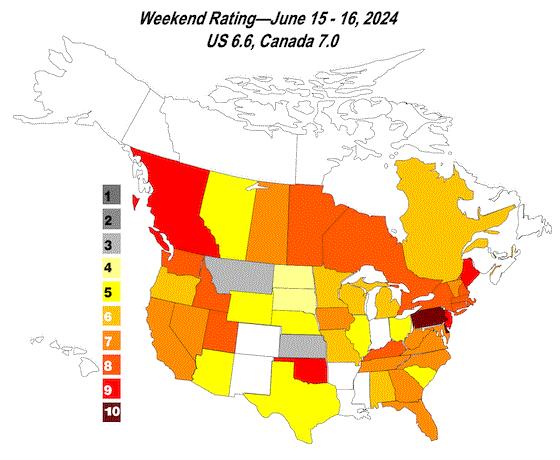

June 15-16: Another “meh” weekend

Maybe even a tad below meh, if meh indicates a score of 7 as sent in by one of my regular contributors. Meh minus would be more like it, as the weekend scoring average for June 15-16 was just 6.6 in the U.S. Canada, at 7.0, hit “meh” right in the bullseye. The weekend before last was a bit better: 7.1/7.2.

Here’s the map:

That’s based on 90 scores from 42 states and six provinces.

The average for the third weekend in June isn’t much above that, at 6.9 in the U.S. and 7.3 in Canada. Last year was much better, however, at 7.9/7.1, so if your score is based on this year’s sales compared to that, well, I can see why it might be tough to beat. Last year, 20% of you scored it a 10 and another 17% scored it 9—so more than a third of you had a great weekend.

This year, only seven of you (8%) scored it a perfect 10. Another six of you (7%) scored it a very high 9, for 15% total rating the weekend as pretty great.

Where was it sweet and where was it sour?

Those seven 10s came from Alabama (that score was based on a 12% increase over the same weekend last year), Delaware, New Jersey (which earned two 10s), Pennsylvania, Quebec and Ontario. Regionally speaking, the East was on top, at 8.6. Next best was New England at 7.9.

The Northwest (7.1) was a mixed bag, with Washington doing well (8.3), Idaho decent (7.5) and Oregon not so much (5.5) due to unseasonable cold and rain. Further north, British Columbia only turned in one score, but it was good, a solid 8.5.

The lowest individual scores came from Oregon (2), Quebec (2), Alabama (3), Illinois (3), Montana (3) and Vermont (3). You sent 4s from Illinois, Minnesota, Nevada, North Dakota, Ohio, South Dakota, Wisconsin and Alberta, Canada. You either said “hot and dry” or “rain, rain, go away.”

All in all, we expect the season to end … but everyone hopes to end with a shout, not a whimper like this season has been for most of you.

To that end, some comments so you know you aren’t alone ...

Your comments

Quebec (2). “I would say 2 for the province of Quebec. Their season is done. It quieted down very quickly this year. The growers are a bit discouraged.”—Mireille Bourgon, Ball Superior

Ohio (4). “It is over. Everyone near me is in BIG SALE mode.”—Brian Sabo, Sabo’s Woodside Nursery

Ontario (5). “Slow and steady is the word around here.”—Carlos Dias, Bradford Greenhouses Ltd.

Alabama (3). “Dropped a little last week with temperatures nearing 100F.”—Davy Wright, Wright’s Nursery & Greenhouse

Montana (3). “Crap for weather. Cold and windy = miserable.”—Ed Hebbe IV, Circle H Growers

North Carolina (7). “Temperatures were hot and folks didn’t want to shop or plant in that heat. Down 20.64% over the same weekend in 2023.”—Jake Scott, Piedmont Feed

Oregon (7). “Below-average cold and rain showers throughout the weekend.”—Ed Blatter, Cornell Farms

Minnesota (5). “Rain Saturday, rain all week this week … We couldn't buy a drop of rain last summer—now its flash flood warnings and thunderstorms.”—Jay Holasek, Fred Holasek and Son Greenhouse

Virginia (6). “Hot and dry … ”—Gary Garner III, Gary’s Garden Center

Wisconsin (4). “Lackluster sales—nothing terribly amazing. Still some movement, however, from customers. Down compared to the previous period in 2023. Not a huge amount of product left for annuals, but enough to keep spending going. I’d love to cast blame on the weather or some local events drawing customers away, but trends are showing that people were focused on their first purchases and aren’t really showing up to continue filling their garden beds. Might be the economy curbing/correcting a bit where previous years’ extra cash was put toward pretty flowers instead of groceries.”—Erik Winer, Mill Creek Gardens

After 41 years in horticulture, I finally visit a peat bog

I’ve used truckloads of peat-based potting mix in my career, but I’ve never been to its source until now. A couple weeks ago, I made my first trip to Canada’s peat country courtesy of an invitation by Premier Tech to visit their campus in Rivière-du-Loup*, about two hours northeast of Quebec. The drive through the countryside was lovely, with glimpses of the St. Lawrence River to my left, with the Notre Dame mountain range beyond that, and the city was larger than I expected, at more than 20,000 people.

The campus is big—250 acres—with buildings old and brand new scattered across it, high-tech labs, and massive open lots of bag-and-bale storage. Because it’s in the middle of 1,900 acres of peat bog, everything has to be built on pilings driven down to bedrock. There’s a daycare onsite and even a university—University Premier Tech, founded in 2015 to keep employees at the cutting edge of technological training.

My hosts were Ed Bloodnick, a 37-year veteran of the company and head of their Grower Services department—the eight folks who have all the technical know-how when it comes to potting mixes and crops; and Renée Redmond, communications advisor for their professional division. But I met with half a dozen Premier Tech folks from across the business, including sales, marketing, biology, their machinery division factory … they put me through the paces for a full day!

Some key takeaways from mon voyage:

- Premier Tech is 101 years old this year. They're celebrating “Beyond 100” because they have to look WAY ahead to secure the company’s future. They're working on leases going out 60 years. They’re working on one now that probably won’t open for harvest until 2038, I’m told. That’s long-range thinking.

- The founder, Joseph-Édouard-Émile “Eddie” Albert (1881–1959), saw potential in the natural resources available in Canada, particularly in the vast peat bogs, and in 1923 he founded the Premier Peat Moss Company. His vision was to provide a high-quality growing medium for the horticultural industry. The Albert family sold the business in 1988 to the Bélanger family. Claude Bélanger played a significant role in the early days of the company, and his influence and vision helped set the foundation for its future growth and development under his son, Jean, who today leads the company (I’m told Claude still comes into the office every day and that Jean has four kids just starting to get involved in the business, so it looks like there’ll be a third generation).

- Premier Tech is actually five companies under one umbrella:

Premier Tech Growers and Consumers: This is the division we know for peat, potting mixes and the biologically active ingredients mychorrhizae and Bacillus. Within it, their Professional division serves ornamental horticulture, agriculture and medicinal ag markets.

Premier Tech Systems and Automation: When Premier Tech needs a machine to handle peat, they can’t just go buy one. So they design and build their own, and also sell those machines around the world. They started with peat, but now they make machines for bagging, compressing, bailing and palletizing of most any product. For example, while touring the factory, I saw machines labeled for delivery to Gorton’s Seafood.

Premier Tech Water and Environment: Specializes in water capturing, treating, recycling and septic systems (their Ecoflo sustainable septic system uses coco fiber for filtration).

Premier Tech Digital: Makes software and apps for production line visualization, optimization and maintenance.

Premier Tech Life Sciences: This newest venture is studying “innovative nutrition products, aiming to improve the health and well-being of humans and animals.” They'll tap into their plant-based and microbial assets and their expertise in biotechnologies and bioprocesses.

- It’s a big organization: About $1 billion (CAN) in sales, 5,200 employees in 28 countries, with factories or plants in 16 countries. They call it “glocal”: Working locally across the globe.

- As for peat, they have 27 bogs in Quebec, Manitoba, Saskatchewan, Alberta, New Brunswick and even Minnesota. And they have 20 plants in North America for processing peat, plus three plants that make their biological active ingredients (more on that below).

*Having studied French in college for six full weeks, I thought it meant where there’s a loop in the St. Lawrence River. But “loup” is French for wolf. It could be named for actual wolves or a native tribe called Les Loups or for the seals, called loup-marin (sea wolves) once found at the mouth of the river.

At the bog (or on the bog ...? In the bog ...?)

My chief objective was actually seeing peat moss—standing in the middle of a bog surrounded by the stuff. I got that at their “President Ouest (west)” bog (above), located right up the road from HQ and supposedly one of their best and most dependable—hence the name. It’s a 600-acre bog that’s been in operation since the early 1990s.

President Ouest peat bog.

But back the truck up a sec—what is peat moss? It’s the composted remains of sphagnum moss, the squishy stuff growing on the top foot or so of an untouched peat bog, and other bog plants growing in depressions left by receding glaciers. These depressions tend to have low pH, low mineral content and just the right amount of moisture—not deep enough to become a pond or lake. It’s not a prime foraging habitat for large animals and the plants that grow in them are specialized—primarily the acid-loving Ericaceae family (rhododendron, blueberry cranberry, heather and such).

A working peat bog looks and feels a lot like any rich-soiled agriculture field right before planting: a brown sea all the way to the black spruce-lined horizon. Along the center road are long windrows of harvested peat drying and waiting for transport to the plant where it'll be cleaned, graded and blended.

Blended? Yes. Peat comes in several quality grades; to achieve consistency, various grades are blended together—like a vitner blending wine—so every bag you get, whether pure peat or a potting mix, is consistent. We saw piles that were lesser grade and piles that were higher grade. It was hard for me to know what was what, but the experts study the fibers and the color and such and know just what it is and what it’s good for. From this bog, they’ll harvest about 5 million cubic feet of peat per year—enough for 1.3 million 3.8 cubic foot bales.

Raw peat moss.

I was excited to see the actual peat vacuum harvesters in action, sucking up the top thin layer of loose peat. Some are self-contained; others are big vacuum wagons pulled by a tractor. Each year they only harvest a few inches of peat—I’m told that’s mostly a function of weather and moisture; the conditions are only right for a short period during the summer and fall.

Interestingly, during my visit it was exceptionally dry. It looked like you could have sucked up 6 in. of the stuff in one go. But that was unusual and by the weekend it had started raining.

Peat vacuums at work.

They took the time to show me their restoration efforts—yes, peat is renewable: You can harvest it for years and then turn the site back into a natural, flora- and fauna-rich habitat. Premier Tech has led the North American and now global industry in developing restoration techniques.

One 10-acre corner of this bog has been in restoration just three years, but already the native vegetation—including sphagnum—is gaining a foothold. They do that by harvesting vegetation from a donor bog. They chop it up and spread it across the area, restore the natural water flow and then let nature take its course.

One 10-acre corner of this bog has been in restoration just three years, but already the native vegetation—including sphagnum—is gaining a foothold. They do that by harvesting vegetation from a donor bog. They chop it up and spread it across the area, restore the natural water flow and then let nature take its course.

Across the street is a fine example of restoration after about 30 years. Called the Sphagnum Garden, it’s a former working bog that now is as pretty a piece of natural Canadian landscape as you’d want to see. The only signs that it once was a working bog are the juvenile trees and some mounds in the terrain (which have to be pointed out to even notice).

The Sphagnum Garden.

The Canadian peat industry is working diligently with government and industry to ensure the long-term viability of peat as an agriculture product. So while there may be occasional shortages due to weather-related harvest issues, hopefully, nobody will decide that peat needs to be banned for a non-existent reason.

Me, with Ed, Renée and Pierre-Oliver Jean, their Natural Resource Manager for North America.

A bit about biological active ingredients

Premier Tech sold its first peat moss in 1923 and its first bag of PRO-MIX potting mix in 1968, but they had bigger ideas. In 1983, they started the Premier Tech Research Center to look at ways to use an exciting fungi that everyone was talking about: mycorrhizae. By 1989, they were adding it to PRO-MIX. Pretty amazing it goes that far back, eh?

Hey, did you know that mycorrhizae can increase the absorption area for water and nutrients by up to 100 times? That’s what the scientists say.

Anyway, Premier Tech has pioneered the high-tech production of mycorrhizae in “mycoreactors,” and at one time, were the largest producer of it in the world—they may still be, they say. In addition, they produce another fungi, Serendipita, and two beneficial bacterium—Rhizobium and Bacillus. These two are made in fermenters. While I was shown some high-tech genetic laboratories, I wasn't invited to see the production of their active ingredients—I reckon for both sanitation and secrecy reasons. You know, the old, “I could show you, but then I’d have to kill you” deal that us inquisitive journalists get several times a week.

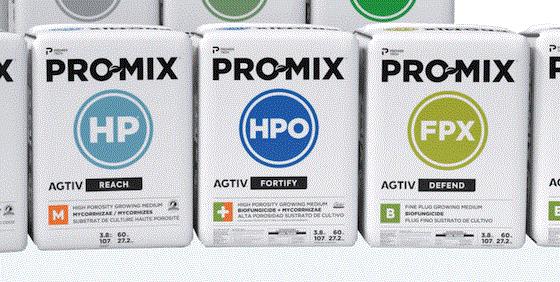

Anyway, cutting to the chase, on July 1, Premier Tech is launching their PRO-MIX potting mixed containing biological active ingredients under a new co-brand, AGTIV, and with it comes a new look and new nomenclature that should make it even easier to know what you're getting. For instance:

AGTIV Fortify contains Bacillus and mycorrhizae. The idea is that the two biologicals protect (fortify) the root system with an expanded barrier against pathogens* and improves nutrient and water absorption.

AGTIV Defend contains Bacillus, which defends plants against root pathogens*.

AGTIV Reach contains mycorrhizae, which helps plants to “reach” and absorb more nutrients and water

*Suppresses root diseases caused by specific pathogens (such as Fusarium, Pythium and Rhizoctonia), and also suppresses fungus gnats and thrips.

Learn more about it at PTHorticulture.com or visit their booth at Cultivate’24.

The first CuttingEdge in North America

Jen was in Canada a while back, too, at George Sant & Sons, when they told her they were awaiting their newest tool, a CuttingEdge cutting sticker from TTA. Here's her report on that:

If you saw the cover of the March issue of GrowerTalks, you may recall seeing the new transplanter from TTA called CuttingEdge. Bossman Beytes saw it in person when he was at the IPM Essen trade show back in January.

At last year’s Cultivate show, the CuttingEdge was so new that TTA only had a video showing the machine, but that was enough for Ron Sant and his son, Miguel, of George Sant & Sons in Kleinburg, Ontario, Canada, to go back and tell Ron’s brothers all about it, and the decision was made to buy one.

In late April, Sant’s new CuttingEdge machine arrived, making them the first grower in North America to have one. I reached out to Ron and Miguel to see how they were enjoying their newest labor-saver.

“In terms of sticking quality, it’s very impressive. There were hardly any hiccups,” Miguel said.

Sant does have other transplanters that they use in the greenhouse, but the difference with the CuttingEdge is that TTA created their own software program that makes cutting detection models for each grower, handling a wide range of different crops. Sant’s URC supplier sends a list of plants directly to TTA, who takes pictures of the cuttings and adds it to the system.

So far, the Sant team has observed that the CuttingEdge will stick more than 2,000 URCs an hour, in 50, 102 and 207 trays. To compare, during an eight- or nine-hour day during peak season, a temporary employee can stick anywhere from 5,000 to 6,000 cuttings a day—maybe 750 an hour. The CuttingEdge does 2,000 cuttings per hour, effectively replacing three or four people.

The machine also offers more consistency across all trays. You don’t get that with three or four employees who've been trained, but who may all stick cuttings differently. With the CuttingEdge, Sant only needs to employ two people to run it—one to feed the trays in and load cuttings, and another to monitor the sticking quality and take the trays out. And Sant’s can run the machine for 20 hours at a time during peak, if necessary.

Miguel said you do have to make sure the cuttings are spread out a bit to make it easier for the arm to pick up the cuttings properly because it doesn’t have a vibrating conveyor belt, but Ron estimates that its accuracy is over 95%.

They haven’t used it to transplant directly into finished containers, like a 4 in.—Miguel said it’s not really set up to do that. But TTA did tell them that down the line they can use it for tissue culture and rooted cuttings, too.

“They’re the new kids on the block, so they’re exploring a lot right now,” said Ron of TTA.

For now, Sant’s is testing it with different crops. When we chatted, they were using the CuttingEdge to stick pennisetum cuttings. Now they'll be using it for mums.

“I imagine this would be good for small- to medium-sized growers,” said Miguel. “It is a bit smaller than other types of machines. And just how fast we were able to get it up and running, there was minimal downtime and not much training needed. It’s going to be a very popular machine, I think.”

Miguel continued, “If you factor in how much labor costs are going up, especially in our area, this kind of investment is almost a no-brainer. If you’re looking at least five years into the future where you’re planning to continue to do this, you kind of almost have to.”

If you want your own CuttingEdge machine, make sure you contact TTA and get on the list because Ron and Miguel’s rep told them there’s been a lot of interest, so demand will be high.

You can watch the Sant folks using the CuttingEdge machine by watching a video they posted on their LinkedIn page.

Finally, eh?*

Since this seems to be the “O Canada” issue, in a couple of months (August 25-31), the International Garden Center Association’s annual “congress” (tour) will once again be in North America, this time in Quebec, Canada—specifically Montreal and Quebec City. I like to promote the IGCA because Laurie and I have been on eight of their congresses, and each one has been different and special. The places you see and the people you see them with are first-rate, the best of the best. I’m now friends with some of the best garden center owners and managers from about 15 countries, thanks to IGCA. I’ve even dined with the president of Ireland.

In Canada, you’ll not only see garden centers, but also the world-renowned Montreal Botanical Garden and other fantastic gardens, and you’ll enjoy cultural visits in both Quebec City and Montreal. IGCA always promises to enrich your knowledge and expand your professional network.

Register before July 24 to make sure you get a seat on one of the luxury motorcoaches!

Watch THIS VIDEO about it if you want to get really excited!

*Why Canadians say eh?

Feel free to email me at beytes@growertalks.com if you have ideas, comments or questions.

See you next time!

Chris Beytes

Editor-in-Chief

GrowerTalks and Green Profit

This e-mail received by 28,856 loyal readers!

Thanks to my loyal sponsors, who help me reach the 28,856 readers of Acres Online in more than 60 countries. Want to be one of them (a sponsor, that is)? Give Kim Brown a shout and she will tell you about our many advertising opportunities.