The 10th Annual Indoor Ag-Con Recap

What a difference from five years ago—the last time I attended Indoor Ag-Con—to this year. The size of the trade show floor back then was a third of what it was this year, with more than 130 companies exhibiting in 174 booths. That’s double the amount of booths from last year, too.

The attendees responded, flocking to the show from 48 states in the U.S. (plus D.C. and U.S. territories), as well as from 29 other countries. All told, more than 1,450 people attended—a 62% increase over last year, according to the fine folks at Indoor Ag-Con. Then add on about 200 more attendees from the co-located National Grocers Association Show.

The room was packed for Plenty Unlimited CEO Arama Kukutai’s keynote speech.

“This tremendous response from the industry—particularly our growing international audience—positions Indoor Ag-Con as the global event for CEA and confirms the growing importance and potential of vertical farming and controlled environment agriculture,” said CEO Brian Sullivan in a recap released after the show. “As we continue to evolve and adapt to the changing needs of our community, we are committed to delivering a high-quality event that provides unparalleled education, networking and business growth opportunities for our attendees and exhibitors.”

What I noticed most was that adaptation to the audience and their needs. When I attended five years ago, there was a greater focus on cannabis, mainly from the attendee perspective. This year, talk of cannabis was present, but by and large, attendees were focused more on leafy greens, veggies, fruits and herbs (of the culinary kind), and the panels and trade show reflected that interest.

I talked to quite a few people at the show, and all were happy with the turnout, focus and future of the show. It’s one of a select few events that’s specific to indoor produce growing. The only negative I heard was about the location in Las Vegas (a sentiment I echo)—it’s expensive. Not going to lie ... I almost laughed in the face of the Dunkin worker who told me my breakfast sandwich and medium coffee was $18.02.

The show stays for at least one more year, though, as next year is set for March 11-12, 2024 in Caesar’s Forum (which is a very nice facility and had a great setup for the show).

More of My Thoughts On the Show

Some other aspects of the industry also became apparent to me at the show, both through listening to panel discussions and in my interactions on the trade show floor:

- The venture capital that’s been infused in the CEA industry up to this point is constricting. That’s leaving producers looking for other ways to fund their operations, hence Plenty’s announcement of partnering with a realty company, for example (more on that below).

- I anticipate more consolidation in the near future as we see operations with greater access to capital looking to scale up.

- More farms are moving out of the fact-finding phase and are starting to actively look for and invest in the systems they'll use to build their farms.

Me, left, moderating a panel discussion on creating a new category at retail for CEA with Mark Gagnon, senior vice president of sales at Kalera, Inc.; Alexander Oleson, CEO and co-founder of Babylon Micro-Farms Inc.; and Dave Vosburg, CIO of Local Bounti.

- I’m hearing about more interest in diversifying product offerings to create more interest at retail. In the session I moderated on creating the CEA category, Dave Vosburg, CIO for Local Bounti, talked about creating salad kits to set themselves apart and fill retail needs.

- There’s a lot of ag tech being developed out there, but it’s a challenge for farms to figure out how to incorporate them either into existing or new builds. Integrating five or six different technologies that don’t necessarily talk to each other or existing systems is a big undertaking and expensive.

- I still heard a lot of "us vs. them," whether it was vertical farms, greenhouse growers, container farms or field ag. There are a select few, however, beginning to work across methods to create hybrid operations.

- I heard more calls for collaboration and less secrecy, which is something I’ve been hearing at every event I’ve been to in this space. It’s part of what will move the needle in CEA.

- The other two challenges talked about at the show that will move the needle is breeding specifically for CEA (see our February cover story on the Inside Grower website about that) and increased efficiencies to achieve cost parity with field grown.

Indoor Ag-Con is proving itself to be one of the go-to shows for CEA production in the industry, and don’t forget they’ve expanded their offerings to include the CEA Summit East in the fall in conjunction with Virginia Tech. That event runs September 19-20 at the IALR Institute Conference Center in Danville, Virginia.

Plenty’s $1 Billion Partnership (and What it Means)

About a week before Indoor Ag-Con kicked off, the vertical farm Plenty Unlimited announced it entered into a strategic agreement with Realty Income Corporation that provides for up to $1 billion of development opportunities. I was able to sit down with Dan Malech, senior vice president of strategy and general counsel for Plenty, to find out what this means for the future of the business.

First, a refresher on Plenty, which has a vertical farm in Compton, California, to grow leafy greens, an R&D facility in Wyoming and a 120-acre farm campus with the first phase in progress near Richmond, Virginia.

Now, the relationship with Realty Income. “We’re taking the real estate portion of our farms—so that’s the land and building, and the big building systems that would be classified as real estate—and having those owned by our partner Realty Income and then leased to us so we pay rent as part of a long-term lease,” Dan explained. “One of the unique parts of the partnership with Realty Income is that starting with our next farm in Virginia, and then moving forward, we’re going to be doing custom builds for our farms.”

That means no more finding warehouses and retrofitting them. “There are some major efficiencies that we gain in doing that,” he added of the new, custom builds. It’s those efficiencies, in part, that the company expects to reduce the cost of production, along with proprietary breeding coming out of the R&D facility.

He further explained the benefits of funding the farms this way: “One of the advantages to doing it that way is the cost of capital. To date, pretty much everybody has been funding their development of their farms with venture capital, which is obviously more expensive than something like real estate financing.

“So we really view this as a big evolution in how these assets get funded going forward to cheaper and more infrastructure-like costs of capital versus pure venture, which frankly is not a scalable way to finance many of these facilities at an industrial scale.”

I also asked Dan about his thoughts on automation, expansion plans and where the gaps still are in CEA production. More on that in a future issue of Inside Grower.

What to Consider Before Starting (or Expanding)

Prior to the start of the show, the folks at Agritecture held a workshop for those looking to learn more about how to get started in CEA. The session fit perfectly into Agritecture’s wheelhouse because the company specializes in helping people invest in CEA or to build, whether it’s a container, an indoor vertical farm or greenhouse, complete with vendor partners who can provide financing and equipment.

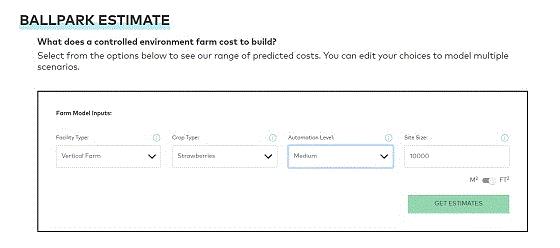

In fact, the company just launched its new software modeling tool in January called Agritecture Designer where you can “build” your growing operation and get financial projections, fair market prices for crops and see estimates related to payback, depreciation and other detailed information.

Why?

“Our goal is to help you understand the importance of planning,” said Jeffrey Landau, director of business development.

Receive estimates on your potential build or expansion through Agritecture Designer.

These tools can help new CEA companies save time and money by understanding the business before they jump in. For example, Jeffrey said it’s critical to understand your business model. What are you passionate about? Are you approaching CEA to create a local food source to combat food deserts? Are you keying in on rising demand for fresh, local produce?

A couple more notes from this workshop:

- There’s no silver bullet when it comes to technology. They all have to be integrated into a growing system and all of them have trade-offs.

- Research integrating new product lines before you jump into them to make sure your production system is compatible with the crop.

- Also, make sure there’s a consistent buyer or buyers for the product line(s) before you begin.

- Grocery, food service and restaurants have a more demanding market entrance than farmers markets; there are less requirements to sell at a farmers market.

- Other options include joining other farmers in a Community Supported Agriculture (CSA) program and on-farm sales (customers pick up items at the farm).

- In Agritecture’s most recent CEA Census, some of the bigger mistakes were scaling too big, too fast and not understanding the market; 49% said they didn’t have any experience before they started in CEA.

You can find more information at Agritecture’s website and poke around a free trial of Agritecture Designer.

New Products: Mushrooms & Biologicals

Two separate products, of course.

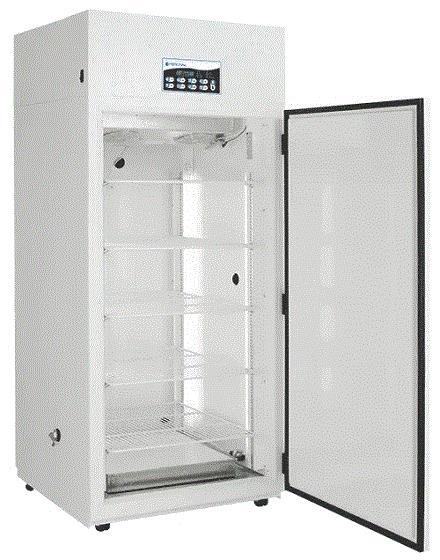

On the mushroom front, Percival Scientific, known for its growth chambers, has a new option for those interested in growing mushrooms. The Percival Model M-36VL with standard IncuWhite lighting is smaller and ideal for studying mushrooms or fungal biology, as well as growing small batches, and the features have been optimized for multiple types of fungi, molds and mushrooms.

I talked with Sales Manager Jamie Jackson at the show, and he said the company is seeing more interest in growing both culinary mushrooms and psychedelic mushrooms (right now only Colorado and Oregon have legalized them, but more states are investigating it), hence the new growth chamber. Mushrooms require low light and high humidity, and require CO2 removal—these chambers are equipped with the controls to provide the right environment for both mushroom inoculation and growing on to harvest. The company also offers a larger walk-in version of the chamber for those who need a bigger growing area.

Jamie noted the smaller chamber is basically plug-and-play after hooking up a water line for the humidifier, while the larger version has a little more to the install.

BioBee just introduced a new format for delivering the parasitic wasps Encarsia formosa and Eretmocerus eremicus to control whitefly in the greenhouse. These clever balls made of biodegradable plastic protect about 15,000 pupae as they're hung in the plant canopy. The wasps can exit the balls through small holes to begin their hunting.

Kyle Miller, technical sales representative at BioBee, said the balls are in response to a problem they found growers having in deploying beneficial insects glued onto cards—workers were accidentally crushing them by gripping them where the pupae were glued. This way, the pupae are protected from workers and the elements.

Growers can get the balls with only one or the other wasp, depending on the type of whitefly they have. Or, if they have greenhouse and silverleaf whitefly, they can get a mix of both wasps. Kyle said, too, BioBee will work with the grower first to determine what type of outbreak they have to make sure they get the right wasps.

More Products: Tomato Yield & Nanobubbles

Again, two separate products.

IUNU introduced its new LUNA tomato imaging system with AI to monitor pests, track crop metrics and enable growers to forecast crops more accurately. The system has 14 cameras on a 10- to 14-ft. tall structure that fits onto a standard tomato production trolley.

Workers can conduct their normal operations up and down the row while the LUNA system works in the background. Growers pay for the hardware, then a monthly subscription service to receive the data. This is the second LUNA system IUNU has introduced—the first is an overhead imaging system for leafy greens production.

The nanobubble technology from Moleaer is not necessarily new, but I wanted to point out some case studies the company has now highlighting the efficacy of the product. Here’s the definition of nanobubble from a case study on strawberry cultivation, in case you’re not familiar:

“Nanobubbles are tiny bubbles filled with air, oxygen or another gas. These nanobubbles are invisible to the naked eye and are 2,500 times smaller than a single grain of table salt.

“At this size, bubbles exhibit extraordinary properties. For example, they no longer float to the surface and pop, instead they dissolve slowly and evenly throughout the entire body of water. Increased oxygen in the water and root zone allows for healthier root development, which leads to increased nutrient uptake.”

In that same case study, the research found a 14% yield increase and 74% lower Pythium counts in strawberry production. The nanobubble technology also serves as a mild oxidant, which means it can reduce pathogens, biofilms, algae, metals and other contaminants, according to the study.

You can find out more about nanobubbles HERE and read case studies HERE. Also, this isn't just for CEA commercial production—there are applications for floriculture, too.

Final Thoughts/What’s Next

I still have some more details from panel sessions, a pre-show interview with a company that reached out before the event and more products. So stay tuned to the next edition of Inside Grower and check out the print edition in May for show coverage.

Did you see something there you want me to talk about? Or did you hear an interesting panel discussion or speaker? I didn’t get to all of them, unfortunately. Drop me a line at jpolanz@ballpublishing.com to let me know!

Also, while I didn’t get out a whole lot while I was in Las Vegas, I did get to check out the conservatory at Bellagio (my favorite place in Vegas) with Kim Brown, Ball Publishing account manager. Here’s a pic in case you missed it. I also bought a piece of cake from a Cake Boss vending machine (only in Vegas), but you don’t get a pic of that (it was delicious, by the way).

As always, feel free to email me at jpolanz@ballpublishing.com with comments, questions, news and views.

Until next time,

Jennifer Polanz

Editor-at-Large

Inside Grower

This email received by 29,495 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.