Vertical Farm Research via Vineland

Ontario is a hub of indoor growing innovation and now there’s additional solutions coming out of the region thanks to a partnership called the Greenhouse Technology Network (GTN).

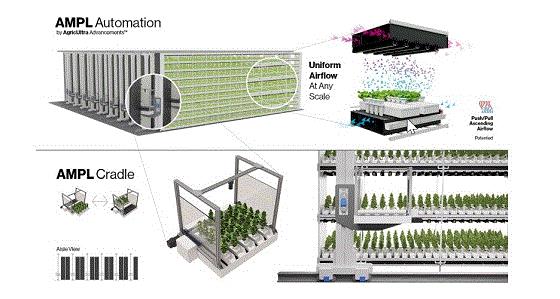

The Vineland Research & Innovation Centre is a part of the network, along with an Ontario-based company called AgricUltra Advancements. The partnership has resulted in an innovative new crane-like tech that takes its inspiration from high-speed automated warehouses.

“We’ve always felt traditional methods of growing in a controlled environment are labor-intensive and backbreaking for workers,” said Emil Breza, president and co-founder of AgricUltra, in an announcement about a prototype to automate movement of grow trays in and out of a growing unit.

In addition to being fully automated, the system allows the user to collect data on all aspects of the plant’s life and spot treat problems when needed.

“With this system, we are taking indoor agriculture to a whole new level,” Emil says. “We can literally measure a plant’s growth rate day-by-day, and with an ultra high-resolution camera installed in the cradle, we’ll have access to biometric markets you wouldn’t otherwise see.”

AgricUltra is also integrating UV application tech into the prototype both for sterilizing surfaces, but to also treat harvest-ready crops. The announcement notes research has shown applying UV to strawberries can extend shelf-life.

You can read the full announcement here and visit Vineland’s website for more research related to indoor ag.

Year-Round Berries?

That’s the goal of another research project in Canada taken on by a team that includes Kwantlen Polytechnic University (KPU). They would like to find solutions to help growers grow berries “sustainably and competitively out of season.” The team received $50,000 in seed funding to write a proposal for the next phase of a larger competition to develop tools to “future-proof” food production in Canada. That competition is being funded through the Weston Family Foundation’s $33 million Homegrown Innovation Challenge.

“The challenge encourages collaboration between academia, industry and other partners to support food security in Canada by bringing our innovations and ingenuity to build systems. It’s a wonderful altruistic gesture,” says Dr. Deborah Henderson, director of the Institute for Sustainable Horticulture at KPU.

Dr. Deborah Henderson, director of the Institute for Sustainable Horticulture at KPU.

She adds that growing berries pesticide-free and energy-neutral is the goal of the team, which hopes their proposal will be one of 10 to receive a grant of up to $1 million to create a small-scale proof of concept over 18 months.

“Using alternatives to chemicals will reduce the carbon footprint of greenhouse production and food production in general,” she says.

The proposal also will include other partners to cover areas like energy-recovery, robotics, lighting and integrated pest management. The first-round proposals are due in December and the projects that advance will begin work in the spring. I’ll keep you updated on Team KPU to see if they move to the next round!

Leaf Spot on Peppers

My colleague, Bill Calkins, who writes our Tech On Demand newsletter, had an item recently that I wanted to pass along:

As always, fall crop production leads to many calls, emails and texts to the Tech On Demand team. Like the tip above, a grower reached out with leaf spots, but this time on peppers. The crop was looking good—clean and green—and then all of a sudden, “it just exploded into leaf spots.”

When the tech experts looked at the photo, they agreed it certainly appeared to be Xanthomonas. Thankfully, they could pass along THIS ALERT from our friends at e-GRO. According to the alert, minimizing wetness—especially at night—is a good way to avoid this disease. Try to water early in the day and not just before dusk.

Another strategy to minimize risk and spread of Xanthomonas is to avoid handling plants when they’re still wet. And—you can probably guess this one—greenhouse sanitation between crops is critical. Bacteria can survive for a long time, so as they say, start clean and stay clean.

Also, a shout out to Bill and the entire Tech on Demand team for being awarded the 2022 Outstanding Education Materials Award—Multimedia from the American Society for Horticulture Science (ASHS). Congratulations and well-deserved!

Upcoming Events

There have been a lot of CEA-focused events and workshops recently announced. Here’s a quick rundown of what I've received in my inbox recently. If I’ve missed anything coming up, email me at jpolanz@ballpublishing.com and I'll get it in my next enewsletter toward the middle of the month.

This one is hot off the presses, as it just came in today. GLASE, the lighting consortium, just announced it's having an in-person summit on Efficiency and Sustainability in CEA. The event will run November 7-8 at Cornell University in Ithaca, New York. There will be speakers, round tables, networking and tours. Visit glase.org/2022summit to found out more and register.

Early bird rates are now available (until September 14) for CEA Summit East, presented by Indoor Ag-Con, October 25-26 at the IALR Institute Conference Center in Danville, Virginia. CLICK HERE for more details.

The Organic Growers Summit 2022, which runs November 30 – December 1 in Monterey, California, will host a CEA-focused session on “The Growth, Opportunities and Future of CEA Production.” Moderated by Tom Stenzel, Executive Director of the Controlled Environment Agriculture Food Safety Coalition, the session’s panelists include Arama Kukutai, CEO of Plenty; Molly Tabron, Director of Supply for Robinson Fresh; and Matt Ryan, CEO of Soli Organic. CLICK HERE for more details.

If you can’t get out to travel, but would still like educational opportunities, Cultivate On Demand is here for you. AmericanHort has extended access to the On Demand portion of Cultivate’22 until September 30. CLICK HERE to see the full list of On Demand courses and CLICK HERE to register.

A Fun Look at Print Magazines

I started my career at a newspaper where we printed our daily editions right on site (a rarity these days)—it’s quite a sight to see. So, of course, I jumped at the chance to take a two-hour ride with my co-workers from the Ball offices up to Wisconsin to check out how GrowerTalks/Green Profit and, of course, Inside Grower, is printed.

We actually got to see our covers on the press as it streamed by at 40,000 pages per hour (it’s FAST). And, I found it: the red button. You know the one—you get to press it as you yell “stop the presses!” I didn’t, though. Enjoy this fun recap from our videographer Osvaldo Cuevas who captured the process from plates to shipping.

As always, feel free to email me at jpolanz@ballpublishing.com with comments, questions, news and views.

Until next time, stay safe and be healthy,

Jennifer Polanz

Editor-at-Large

Inside Grower

This email received by 28,933 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.