Two … no, THREE

Last time, I wrote about some plant trends and products from my recent trip to the Netherlands, and I promised you two bits of cool greenhouse technology this time. I’m keeping that promise; in fact, I’m overdelivering by 50%. After that, more industry news, including, I’m sorry to say, an obituary, but also a better idea than plastic crap for the kiddos at Christmas.

The new white house

My new friend Kick Jansen*, international sales manager for Luiten Greenhouses, took me out to see what is probably the smallest new greenhouse in the Netherlands, MediaVerdi, in Aalsmeer. By small I mean 26,000 sq. ft., or about .6 acres. But it’s pretty high-tech, with three different curtain systems on two layers, a bright white paint job on virtually every metal surface (for maximum light reflection), in-floor heat, and some amazing diffused glass (more on that in a moment).

The greenhouse structure, which replaces a wood and glass structure from the ’60s, is by Nobutec. Luiten supplied the three-layer curtain system: 50% shade on top, and an energy curtain and light pollution curtain below (to prevent night lighting from annoying the neighbors). Luiten is also installing horizontal curtains to divide the house into six growing zones.

Three generations of the Buis family: Coos, Jeroen and Johan. Eighteen-year-old Jeroen did a short internship at Green Circle Growers this past summer and also attended Cultivate. He hopes to bring back one of the family’s former crops, lilac, which his grandfather grew.

In the new facility, three generations of the Buis family will continue growing what they have since moving to the site in 1901: cut flowers. During the winter they force snowball viburnums for cut flowers; in the summer they switch to large-flowered carnations. Seventy percent of the crop is presold; the rest goes through the auction.

Viburnums waiting to be brought into the greenhouse for forcing into flower.

*His given name is Chris, but his dad wanted him to be a soccer star, and he's been called Kick for as long as he can remember.

Internal transport by John Deere

As for that internal transport system I mentioned in the email subject line: It’s a John Deere lawn tractor that Johan rigged to run forward and reverse remotely using a small keyfob. A single rail and train-style wheels keep it on the straight and narrow. It hauls trailer loads of plants in from their outdoor growing area, allowing one person to move product without climbing on and off the tractor each time they need to move a few feet. It works so well, Johan is on his second tractor—he wore out the first one!

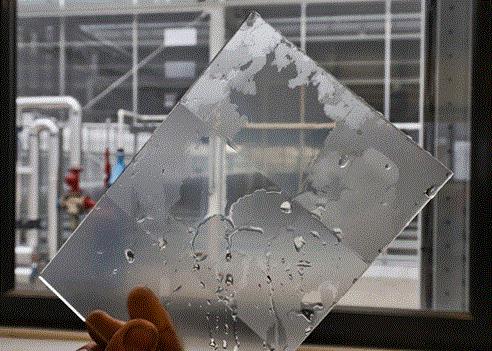

SmartGlass: turns clear when wet

Diffused glass is great stuff for making the light in a greenhouse more even and uniform. But that diffusion comes at the cost of a few percentage points of added shade—something a northern grower doesn’t need, especially in the winter. And what about when it’s gray and rainy out? Doesn’t that make it even darker inside?

MediaVerdi’s new house features special diffused glass that, when wet, such as with rain or condensation, turns almost transparent. Here’s proof:

They couldn’t tell me much about the glass there at the greenhouse, so I did some digging when I got home. I learned it’s called SmartGlass, available exclusively through Glascom International in the Netherlands. One of their experts, Michiel van Spronsen, told me via email that they introduced SmartGlass five years ago in Europe and North America. Designed for greenhouse use, it has some special features:

- It is “hydrophilic,” so condensation or moisture forms a film instead of drops, and the water will flow down to the gutter. Most other glass products are “hydrophobic,” meaning condensation or moisture form droplets, which can cut light transmission by as much as 6% (and fall from the glass onto the plants).

- It has “adaptive-haze” properties, meaning that when the glass is dry, the haze is high, and light-transmission is high. When the glass is condensed or wet, haze will drop, but light transmission will increase, especially in the angles of incidence between 40º and 70º.

- Because of its smooth surface, SmartGlass has a very uniform diffusion, which results in a high “hortiscatter-value.”

- Also because of its very smooth surface, almost no dirt will stick to the glass.

- Tests have shown that, whether tempered or non-tempered, SmartGlass has a higher mechanical strength than patterned glass, which might be interesting for hail-prone areas.

And why diffused glass vs. regular? Wageningen University, one of the leading universities in the horticultural field, has concluded after years of trials that diffused glass offers a more equal climate in the greenhouse (fewer “hotspots”), a more equal temperature distribution over the plants (less difference in temperature between the top and the lower leaves), almost no photoinhibition (light-induced reduction of the photosynthetic capacity of a plant), higher photosynthesis, and a better microclimate within the greenhouse.

Got questions about SmartGlass? You can email Michiel at vanspronsen@glascomtuinbouw.nl.

Flier Systems’ Young Plant Sorter

There’s nothing new about using cameras and computers to grade and sort plugs and cuttings. What is new is that this machine by Flier Systems (represented in North America by AgriNomix) analyzes pictures of the root zone as well as the green portion of the plant. I saw it in action at perennial liner grower Gebr. Alkemade in Lisse.

This version of the Young Plant Sorter was originally developed for the tomato business. Alkemade’s owners, Theo and Wil Alkemade, thought it could help them reduce labor, save space and improve the quality of the 25 million perennial liners they grow and sell annually.

Why grade, and why the roots? Theo and Wil grow more than 1,000 varieties of perennials in several dozen genera, almost all from cuttings, in about 300,000 sq. ft. of greenhouse. Cuttings that don’t root or are smaller than desired can waste a lot of that expensive space, so grading and sorting is essential. Done by hand, it’s slow and labor-intensive, requiring upwards of 30 people during peak times.

The Young Plant Sorter lets Alkemade grade early in the production process—as soon as three to four weeks after sticking, thanks to the use of Grocoons as their rooting container (they hold the root ball together until it has developed).

The machine’s Aris cameras look at three things: The top of the plant (looking down), the side view of the plant, and the side view of the roots. The grower inputs how much of each they want, and the machine then sorts into three grades—you might call them best, good and trash. All the best liners go together into one tray, the good liners go into another tray, and both lots go into the greenhouse for growing on. Trash obviously goes into the trash. The inset photo shows the three views the camera gets.

Early in the process, they grade by looking at the top of the plant, just to see if it has survived. Later on, they can grade by the green portion and the root system.

Being able to grade the roots is important because many perennial genera will develop good roots first, while still having little green growth. Those varieties can get sorted with good roots as a priority.

The machine does it all with 13 grippers and three cameras. Speed is optimized at 8,000 plants per hour, although workers Marius van Duijn and Marco van Delft who were setting up the machine told us they’ve hit 9,500. And the machine was just four weeks old when we saw it at work. The desired outcome? “If [waste] is below 10%, that’s good,” said Marius.

RIP Ed Knapton

Our industry lost a well-known grower/retailer earlier this month. Edward John “Ed” Knapton, who, with his wife, Carol, owned American’s Best Flowers in Cottage Grove, Wisconsin, passed away November 6 after a long battle with cancer. He was 70.

Ed, a hort graduate from UW-Madison, was visibly active in the retail garden center world, traveling and touring garden centers across the country. Ed was a past president of Commercial Flower Growers of Wisconsin, an active member of the Wisconsin Green Industry Federation, and a member of the Garden Center Group and the Perennial Plant Association. He was widely known and liked by garden center owners everywhere, and was known for being unabashed in expressing his faith. Even the tagline of the business says, “God’s joy grown for you.”

Online condolences may be made at www.gundersonfh.com.

50-cent Black Friday poinsettias

Just a warning: According to bfads.net, Lowe’s will be offering 1 qt. poinsettias for Black Friday, limit 16 per customer, while supplies last. Should be a feeding frenzy! (But don't worry that they'll ruin your poinsettia business—they'll be forgotten so quickly, you'll have plenty of opportunity for selling quality plants of all sizes at full price.)

No word on Home Depot’s BF offerings yet. Walmart, meanwhile, seems focused on electronics and toys.

Finally I ...

Congratulations to my right-hand man, Paul Black, Publisher of GrowerTalks/Green Profit, who last night celebrated his 15th year with Ball Publishing during the annual gala Service Awards dinner at Ball.

Personally, I give all the credit to Paul's lovely wife, Annie, who has trained him well.

Finally II ...

Reader Beth Weidner sent me a LINK to this quirky Christmas toy, BlumeDolls, that does … or does not … have a relationship to our product. My staff with youngish daughters say it’s definitely a thing.

Ugh. In my expert opinion, forego the plastic junk that will be forgotten by dinnertime and instead go to Ace Hardware on Black Friday and get her this Amaryllis Bulb Kit:

Longer lasting, more beautiful, a bigger surprise, and it might possibly start her—or him, it's unisex—on a life-long journey.

See you next time,

Chris Beytes

Editor

GrowerTalks and Green Profit

This e-mail received by 21,413 loyal readers!

Thanks to my loyal sponsors, who help me reach the 21,413 readers of Acres Online in 66 countries. Want to be one of them (a sponsor, that is)? Give Paul Black a shout and he'll hook you up.