The Colombian cut flower industry

I originally wanted to title this week’s newsletter “Reflections on the Colombian Cut Flower Industry.” Then it hit me—How full of (bleep) am I? There are hundreds of cut flower farms ranging from mom-and-pop operations to huge corporate farms in the Sabana and Antioquia regions of Colombia alone. One thing I’ve learned this week: every farm is different from its closest neighbor in many ways. So, to “reflect” on the entire cut flower industry of Colombia two days after a three-day visit in one region of a vast country is simply ludicrous! It’s more annoying than when someone, after learning that you are from Malaysia, asks if you know Ali.

Okay, back up a week. Last week, Margaret Skinner and Bruce Parker of the University of Vermont and I joined Terril Nell of the American Floral Endowment (AFE) on a tour of seven cut flower farms around Rionegro and Medellin, Colombia. Corina Zambrano of Ceniflores (the research arm of Asocolflores), Marcos Ossa of Asocolflores (The Association of Colombian Flower Exporters), and Juan Carlos Gonzalez and Mauricio Mesa of G.R. Chia SAS graciously accompanied us on different days of the trip.

Margaret, Bruce and I receive research funding from AFE’s Botrytis and Thrips Campaign. The purpose of this trip was for us (the researchers) to understand the production and pest management challenges (specifically against thrips) on the ground in order to adapt our research findings and to develop research ideas that best help the cut flower farmers in Colombia and elsewhere.

More than 90% of Colombian cut flowers are produced in the Sabana (or Savannah, the area around the country’s capital, Bogotá) and Antioquia (which encompasses Rionegro and Medellin) regions. Mums and hydrangeas are the major crops in Antioquia, whereas the higher elevation in Sabana allows for the production of large quantities of roses and carnations. The majority of Colombian cut flowers are produced for export, with the United States as the top destination (about 75% of the crops, which valued at $1 billion in 2013, according to a 2015 USDA report), followed by Europe and Asia. Y’all can find Colombian flowers in all major retailers and groceries, such as Wal-Mart, Costco and Kroger.

We visited seven farms in and around Rionegro in three days. Mums are the major crops in five of them; one farm is a mum propagation facility and the other produces only hydrangeas. The farms are between 15 and 35 hectares (37 and 86 acres), all under cover (plastic or shade clothe). Although I’ve been involved with floricultural entomology for almost 20 years, I’d interacted with less than half a dozen cut flower growers in the United States. None of them have operations larger than a few acres. So, seeing large cut flower farms in operation is an eye-opening experience.

It's true, every farm is this scenic.

By the way, some of you noticed that I misspelled Colombia as Columbia, the armpit of South Carolina in the last newsletter. I thought the Colombians would have a protest at the Medellin International Airport, or at the very leas,t my Associate Dean of Research and my former graduate student (both of whom are from Colombia) would have given me hell. But none of that happened. So, another lesson for JC: they are just not that into you, egomaniac.

I found the Colombian people to be friendly, gracious and proud, as they have every right to be. I found the Colombian cut flower farms to be meticulously run, productive, and take care and pride in their employees. Granted, the farms I visited were considered large, well-capitalized and very sophisticated in their pest management, but they still need technical help.

In addition to many pounds of chicharrón in my belly and beautiful sceneries in my memory, I also brought home observations on pest management practices, challenges and innovations. I want to share these observations with y’all today.

Start clean, stay clean

Let’s start at the propagation facility. This facility produces 350 million mum cuttings per year. Because of its volume, the success and failure of pest management here has enormous down-stream effects. If a grower can receive clean cuttings, they will have an easier time staying clean.

“Zero tolerance for pests" is the operating principle of this facility. You are only partially right if you think, “That must mean they spray like crazy.” Most of the farms I visited do spray a lot of insecticides and fungicides; two to three applications per week are the norm. Most managers and growers we visited desperately want to reduce the frequency of pesticide applications because they want to protect the environment and their employees, reduce costs and produce quality products.

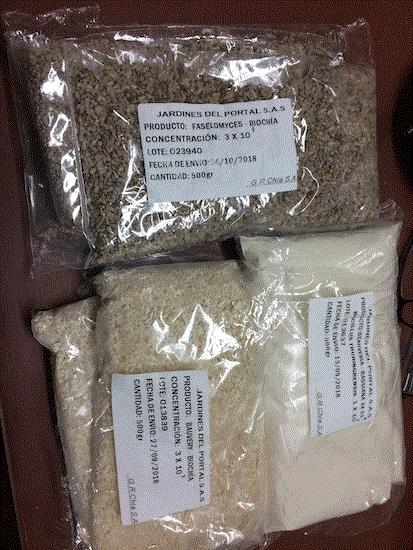

Not all products used are synthetic pesticides. A grower estimated that 40% of applications in his farm were of biopesticides and biorationals. G.R. Chia produces Paecilomyces (as nematicide), Beauveria bassiana and Bacillus thuringiensis (both entomopathogenic fungi) in its own laboratory for use in all its facilities. The strains of these beneficial fungi and bacteria were isolated from the local populations. They are incorporated in dried cooked rice for easy broadcast and propagation, or in power form for mixing in water. Seeing the use of cooked rice for fungi propagation on this trip just tickled Margaret to death. She had developed and advocated the use of cooked millet for propagation and broadcast of Beauveria bassiana.

Biopesticides produced by G.R. Chia SAS for use in its own facilities.

Cuttings from the stock plants are used to propagate “mother plants” in beds. Before planting, the beds are sterilized with steam generated in an enormous boiler. The steam is delivered through metal pipes to the bed, which is lined with two or three smaller perforated pipes along its entire length of about 100 ft. The bed is covered with plastic, and steamed at 90C (194F) for one hour to kill weeds and nematodes. Since all flowers are grown in the ground, this sterilization technique is practiced in most cut flower farms we visited.

This propagation facility uses steam to sterlize its beds.

The cuttings are packed and fumigated with phosphide before being sent to the farms. Each pack of 1,000 cuttings is carefully labeled so that, if the growers find pests or problems, the cuttings can be traced back to specific beds and the problems can be resolved at the propagation facility.

Scouting

Every farm we visited scouts for pests, and most operations have dedicated scouts or an IPM team.

Every farm uses sticky cards or bands. Blue and yellow are the predominant colors, but we also saw white cards. The sticky bands are used both as monitoring tools and traps. One farm even deploys sticky cards around the production houses so that invasion of thrips and the direction of invasion can be detected.

Sticky bands are used as a monitoring tool (top) or traps (bottom).

Most of the sticky cards are hung with wires from the ceiling so that the traps can be moved with the growth of the crops. A different way of keeping the sticky cards just above the top of the plants is achieved by clipping or hanging the cards on a horizontal bar fastened to a vertical stake with a screw and nut. The horizontal bar can be moved up and down along a column of holes drilled on the vertical bar. The grower at this farm gave me permission to steal this idea, and I happily obliged!

An innovative way to hang up your sticky cards.

One of the interesting scouting tools we saw was an insect vacuum. This is a motor-powered vacuum that sucks up insects from the flowers and canopy. When I was a wee graduate student a thousand years ago, I used something similar called a D-Vac. The insects sucked up in the vacuum were emptied into a plastic bag, where they were identified and counted.

The bugs can run, but they can't hide from the bug vacuum.

Bruce and Margaret stressed the importance of maintaining detailed scouting records so that trend in pest population can be identified. The growers we visited keep their scouting records in different ways. I was impressed by the fact that most farms have digitized their scouting data so that the data can be plotted to identify pest population trends and shared among members of scouting or IPM teams.

Sanitation

Cut flower production generates a large amount of debris and refuse. Rejected or unharvested flowers in the greenhouse represent an opportunity for thrips and other pests and diseases to maintain a population and to move onto new crops. The scheduling of production beds requires a logistic system that rivals that of shipping routes. With the best scheduling, however, there are still times when a maturing crop is right next to a harvested bed or a new crop.

A mathematician was hired to develop a logistic system for scheduling beds for production. No joke! Still, a lot of debris and refuse litter the beds immediately after harvesting. The debris in this picture was removed within days.

Growers strive to clean up the debris as soon as a bed is harvested. Most is raked and removed, but one grower has taken a different approach. The debris on this farm is burned using a device similar to what is often used for burning weeds and debris in nurseries.

Burn, baby, burn!

The debris and refuse aren’t wasted. The soil in the Antioquia region is beautiful, with 20% organic matter, and highly acidic. The soil is amended with processed or composted debris and refuse before the next crop is planted to maintain productivity and fertility.

Nothing is wasted. Debris is processed, composed and tilled into the soil.

Post-harvest and finally, customs inspection

Post-harvest processing at the farms is automated. There are still tasks that can only be completed by humans, such as post-harvest pest inspection, grading and packing. The post-harvest facilities we visited were meticulously clean and the floors of almost all of these facilities were completely dry. Dedicated employees clean up every bit of debris and refuse almost as soon as the trash touches the ground. There was never a standing pool of water.

Thousands of stems of cut mums are processed, inspected and packed in this facility.

The post-harvest facilities are air-conditioned for comfort and to maintain crop longevity and quality. You can say the post-harvest facility is the best place to be, but at temps in the low-80s, the field is also quite pleasant. It’s not all work and no play at these farms. At two different farms, a sudden blaring of music interrupted conversations. Employees poured onto open areas for five to ten minutes of organized stretches and exercises. We should do this too!

One of the biggest challenges to the Colombian flower growers and the biggest reason why their pest management programs are so intensive is a low tolerance for insects and mites at customs. Millions of stems of cut flowers arrive at Miami International Airport daily, and many of the boxes are opened and inspected. If an insect is found, the entire shipment will be fumigated before being allowed to move to the distributors. The growers will be billed for the fumigation costs. At the Chilean customs, shipments with insects and mites are often rejected outright and the growers blacklisted. Because of the potential of rejection, fumigation costs and deteriorating post-harvest quality, Colombian growers are doing their best to reduce pest populations during the production, and to detect and eliminate pests during post-harvest. One farm has taken the extra step of inspecting stem-by-stem all flowers bound for Chile if one thrips is found during in-house inspection. This extra step takes place in a screen room to avoid spreading the thrips to other flowers.

Because one thrips was found in a bouquet during in-house inspection, employees had to be reassigned to inspect every one of these flowers destinated for Chile. Thrips-infested flowers were removed from the buoquets and discarded.

Research and extension for the cut flower industry

There is not an official extension service in Colombia. We met with a few faculty members from the National University of Colombia and the Catholic University of Colombia during the visit. University faculty focuses on research and education, and often cannot provide extension services to the Colombian flower growers. Despite their technical handicaps and a lack of funding, faculty at Colombian universities is eager to work with researchers from elsewhere to solve pest management problems in Colombia.

Almost all farms use biopesticides and biorationals. Predatory insects and mites are available (not as diverse and easy to come by as in the United States), but many Colombian growers don't use them. What we have learned is that, because of stringent environmental protection regulations and concerns over the threat of introduced species (most commercially available predators and parasitoids aren’t native to South America), growers and regulators are reluctant to embrace commercially produced predators and parasitoids. An obvious way of promoting the use of these predators and parasitoids is to identify and make available local species and strains. For that to happen, we will need to assist local researchers and biocontrol agent producers in isolating, evaluating and rearing local species.

The cut flower industry in Colombia is clamoring for knowledge and assistance in pest management. I think researchers in the United States can help Colombian flower growers produce crops more effectively, safely and sustainably by providing some basic training on pest management. For example, the hydrangea grower we visited was plagued by broad mites, but he used miticides that are effective only against spider mites. You would think that growers should have the basic information such as what a product is good for, but they often don't. So, I had an opportunity to share my experience on managing broad mites and recommended several effective products.

I’d explained how thrips feed at least six times during this trip. I saw light bulbs being turned on in the growers’ or the pest management technicians’ heads, as if they were understanding, “So that’s how thrips damage a plant and how we should manage them this way!” Tell you what, I love moments like this, and that’s why I work in extension!

See y'all next time!

JC Chong

Associate Professor of Entomology at Clemson University

This e-mail received by 24,717 subscribers like you!

If you're interested in advertising on PestTalks contact Kim Brown ASAP!