Talking about tulips

Tulips: A crop that relatively few growers bother with and also few consumers. Which is a shame because they're one of the oldest commercial horticulture crops. (Remember tulip mania in the 1600s? That was bigger than the houseplant craze of the 1970s!)

I’m as much to blame as anyone for not talking more about tulips: The last time I studied them intently was on a press trip to the Netherlands in 2008 sponsored by the International Bloembollen Centrum (Flower Bulb Center). Other than that, I don’t think I mention them more than once a year, if that. I’m about to make up for that by devoting this entire Acres Online to the things. Stick around—I promise to make it interesting.

Three of my fellow journalists get the shot.

Three of my fellow journalists get the shot.

The Third Annual Tulip Trade Event

My inspiration comes from attending a new (this is year three) event in Holland called Tulip Trade Event. Think Pack Trials for cut tulips—only instead of packs, the crop is grown and shown in the black plastic bulb crates in which they’re grown. Eleven participating growers/exporters opened their facilities for three days to customers, who can view hundreds of cut tulip varieties, grown on both water (hydroponic culture) and peat (the traditional method). Plus, the usual facilities tours, coffees, lunches and chance to talk with the experts.

I attended at the invitation of iBulb, the marketing arm of the tulip industry. I was one of nine journalists from important export countries, which included Finland, Sweden, Norway, Poland, Czechia, Russia, Japan and China. Those (and the U.S.) are big importers of bulbs for cut flower forcing and iBulb is hoping we'll help spread the word in our respective countries about Dutch tulips.

As I said, it’s a new event, just three years old, and it’s modeled after Dutch Lily Days, which is only five years old. It seems the hot thing in the Netherlands is to hold open days for your crop (I understand there’s also a Dahlia Days). We visited three of the 11 Tulip Trade Event participants, plus an equipment company (Havatec), a breeder (Hobaho, a Dümmen Orange company) and one smaller grower, Mooij Tulips, who isn't part of iBulb, but who specializes in florist-quality cut tulips. It was a well-rounded, fast-paced, two-day dive into the market and I learned just enough about the current cut tulip market to be dangerous.

The display of 200 tulip varieties at Nord Lommerse. While there were some new introductions on display, I didn’t see a single “new” sign. Seeing how it takes 20 to 25 years to bring a new tulip to market, you think a new one would be met with spotlights and a marching band.

The display of 200 tulip varieties at Nord Lommerse. While there were some new introductions on display, I didn’t see a single “new” sign. Seeing how it takes 20 to 25 years to bring a new tulip to market, you think a new one would be met with spotlights and a marching band.

What’s hot in tulips?

Novelties, answered Erik Lommerse of Nord Lommerse, our first stop. Doubles—such as Mondiano and Dreamer—are especially hot right now, as are fringed and parrot types. Growers like novelties because they bring more money at auction than the more standard forms.

Mondiano

Dreamer

Dreamer

Crown-shaped flowers are an emerging category, says Dirk-Jan Haakman, third-generation of Haakman Flowerbulbs. He showed us several, including Crown of Dynasty. Green Dance is a lily-flowered tulip from Haakman’s own breeding that’s popular in Japan.

Crown of Dynasty

Crown of Dynasty

Green Dance

Wonder what the number one-selling cut tulip is? It’s called Strong Gold and it’s been around since the 1960s. Of the 30,000 acres of production area in Holland devoted to tulip bulbs, Strong Gold accounts for 2,400 acres. It’s 6% to 7% of Haakman’s annual volume of 145 million bulbs.

Strong Gold

Strong Gold

Ideas? Not so much.

Comparing Tulip Trade Event to Pack Trials is a fair comparison, if we go way back in time to when Pack Trials was only about new varieties and not about marketing. We saw loads of side-by-side tulips, generally organized by color category, but we saw little in the way of inspiration—no big tulip floral arrangements or retail display ideas, for instance. However, it’s a new event, so maybe as they get their feet wet …

One idea we spotted was back in a bulb cooler at our final stop, Mooij Tulips. Third-generation owner Aron Mooij (it seems like every young person we met was third-generation) showed us this product he ships to Italy: cut flowers, still with their bulbs attached, wrapped in a water-tight cellophane bag.

For great bulb ideas, stop at any European garden center. I know from previous experience that the spring containers they offer are second to none.

Tulip breeding is like …

A snail. Or perhaps molasses. In winter. Which is why every new variety is met with fanfare, since the initial cross that produced it was made … well, let’s see, a new introduction this year was first crossed back in 1998 or thereabouts. Practically pre-Internet! Certainly pre-social media.

I asked Dirk-Jan what the Holy Grail in tulip breeding is and he answered, “Speeding up the breeding.” That would allow the industry to stay more current with consumer trends. More importantly, breeders would breed for disease resistance, which would reduce their dependence upon chemicals (already being threatened by regulation) and help them meet ever-more-strict phytosanitary requirements of customer countries.

Hobaho's "back room."

Hobaho's "back room."

To that end, breeder Hobaho, a Dümmen Orange company, is taking a multi-faceted approach to cutting the breeding time in half—an effort they call Tulip Breeding 2.0. That includes university research to reduce the tulip’s long juvenility stage and sequencing the tulip genome to allow for “marker-assisted” breeding and “predictive” breeding. The effort is well underway, says Breeding Director Anita de Haan; they're awaiting the results of the gene sequencing as you read this. Perhaps a cross made today will be on the market in 10 years, instead of 20.

In the meantime, there’s technology

Last time I saw an x-ray machine was at my dentist’s office. I didn’t expect to see one in a tulip greenhouse. But equipment manufacturer Havatec builds sorters and graders for bulbs and cut flowers that can spot fusarium inside a bulb or find a flower hiding behind a leaf. They use that in conjunction with standard cameras to provide amazing rates of speed for the sorting and tying of tulip bunches—critical when a high-volume grower can sell upwards of 2,500,000 stems per week. And some of their machines can handle multiple crops, allowing for use up to eight months per year.

Business must be good for Havatec; they're consolidating their 10 scattered warehouse locations into one shiny new building. I asked co-owner Mark Fikkers about what’s next in automation. One area is lower-cost automation for offshore producers; another is the fruit and vegetable markets.

We saw LEDs being tested in several greenhouses. Aron Mooij has a two-level growing area (above) for his florist-quality cut tulips and under one section we spotted the tell-tale purple glow of LEDs. He’s hoping to get additional stem length with the lights, but it’s too soon to tell if it will work. Breeder Hobaho is also testing LEDs in their research facility.

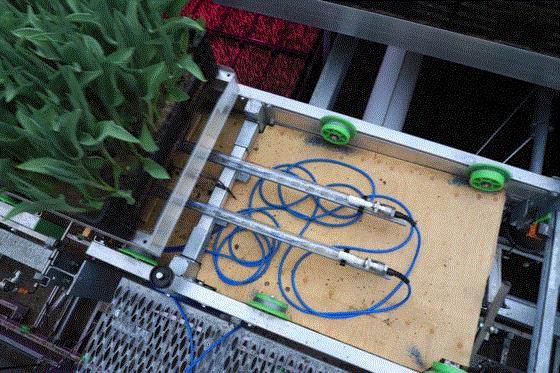

Even cooler at Mooij is the use of UV-C (short-wave ultraviolet) lights for root-zone sanitation. A pair of UV-C lights are located in several spots in the greenhouse below the rollerbahn where the bulb tables travel. As plants pass over the tubes, the UV waves sanitize the exposed roots by rendering any microbes sterile—a slick way to reduce the use of chemicals.

VWS is a major bulb import/export company. They don’t grow or finish any flowers, they just import bulbs, chill them as needed for the market and ship them out to 60 different countries. When they ship them, they pack them in peat moss, and they used a lot of it during the short shipping season. To make sure they don’t run out, their peat bunker is equipped with a camera wired straight to their supplier, who keeps an eye on the pile and sends a truck around with a fresh load when needed.

Finally …

I won’t get into the differences between 5° (Celsius) growing and 9° growing because it’s just too complicated for the layman like me to really grasp. (Suffice it to say that 5° growing is the old-fashioned way, where the bulb blooms when it feels like it; while 9° growing lets the grower program blooming almost to the day.)

As for tulip economics, I assume there’s money in tulips. Everyone we met was in a good mood. Nobody complained about the market. Mooij was in a new facility and Nord Lommerse was building more bulb storage space. Auction prices (the vast majority of cut tulips still sell via the clock) are up and down on a daily and seasonal basis, as they always have been. Sourcing bulbs from contract growers in Chile and New Zealand has expanded the business from a few months to nearly year round.

One thing is certain: the tulip is a crop you can easily underestimate. It looks simple: a big round bulb that almost miraculously sprouts a beautiful flower with that iconic shape. But the work it takes to get it to the garden or the vase? Let’s just say that two days isn’t nearly enough time to begin to grasp the complexities of it all.

But it’s plenty of time to enjoy their beauty!

See you next time!

Chris Beytes

Editor

GrowerTalks and Green Profit

This e-mail received by 22,980 loyal readers!

Thanks to my loyal sponsors, who help me reach the 22,980 readers of Acres Online in 66 countries! Want to be one (a sponsor, that is)? Give Paul Black a shout and he'll hook you up.