12/1/2017

Inputs That Make Cents

Paul Pilon

I’m not a genius mathematician or even savvy accountant, but I understand the importance of making a profit. I’m astounded from time to time how many growers give up profits when they’re under the impression they’re cutting costs by utilizing smaller-sized starting materials. Does an upfront cost savings directly improve the bottom line and increase profits? Not always.

Regardless of whether you’re growing in expensive, state-of-the-art facilities or less-sophisticated production facilities, there’s a cost associated with being in business, often referred to as overhead. Each business will have its own overhead costs and there are several methods of calculating overhead which would be too detailed for this article.

For the purpose of the points I’d like to demonstrate, I’ll focus on the concept of “square foot weeks.” Square foot weeks are essentially derived by taking all of a business’ overhead costs and dividing them by the total square feet of production space and dividing this number by the number of weeks that space is being utilized for production. The value for square foot weeks varies from business to business and usually falls somewhere between $0.20 and $0.40 per square foot week.

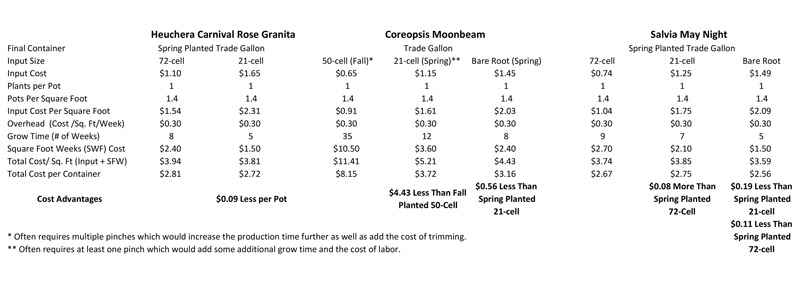

Now let’s look at a couple of examples of how different-sized starting materials can influence production costs. For simplicity, I’m using $0.30 per square foot week, a single input per container and 1.4 containers per square foot for all the examples that follow. The only differences are the types of inputs being used, the cost of these inputs and the amount of grow time required to produce a marketable crop (see table).

Heuchera Carnival Rose Granita

First, let’s look at a fairly straight-forward scenario with Heuchera Carnival Rose Granita. When comparing spring planting large 21-cell liners to smaller 72-cell liners, you’ll notice the 21-cell liners cost more to purchase than the 72-cell liners. However, the larger liner size takes three weeks less to finish than the smaller plugs. As a result, the total cost for both the input and overhead when using the 21-cell liners is $0.09 less per container than when using the smaller input size. Maybe $0.09 doesn’t seem like a lot, but that would be $90.00 in savings for every 1,000 or $900.00 for every 10,000 containers grown.

Coreopsis Moonbeam

If you’ve grown this crop from liners, you already know how long it can take (and how much trimming is necessary) to produce a high-quality plant. Growers who opt to use small liners have the best success when planting and bulking them in the late summer or early fall and overwintering them prior to forcing the plants for spring or summer sales. In this example, I used Week 35 for the plant date and Week 18 for the spring sales date.

As you can see, the costs associated with fall planting 50-cell liners are very high. Keep in mind that I’m not an accountant, but I figure the plants are still occupying production space during the winter and overhead costs are still present this time of year.

For a more apples-to-apples comparison, let’s look at the two spring planted options. From my experience, I find large liners will take more time to grow than coreopsis from bare root. Coreopsis Moonbeam from bare root are shippable in about eight weeks, whereas large liners typically take approximately 12 weeks. Using these finish times, bare root starting materials would cost $0.56 less per container to grow than 21-cell liners. This results in a savings of $560.00 for every 1,000 containers being grown.

Salvia May Night

The last example I have for you is comparing three options for spring planting Salvia May Night. The first notable difference is that the larger 21-cell liner doesn’t offer a cost advantage over using smaller liners; it actually adds $0.08 more per container to the total cost to use the larger input. Bare root starting materials, on the other hand, do offer a cost savings over both liner sizes. Using bare root would provide an $0.11 savings per container over using 72-cell liners and $0.19 over 21-cell liners. This provides $110.00 to $190.00 in cost savings per 1,000 containers when opting for spring planting bare root versus liners.

The calculations demonstrated here are for informational purposes only. Your costs and potential savings will vary from these examples. I encourage you to conduct your own calculations using your actual costs, crop spacing and grow times. Do the math and choose the inputs that make the most cents. GT

Paul Pilon is a Perennial Production Consultant and editor-at-large of the Perennial Pulse e-newsletter. Feel free to contact him with article topics or to address your perennial production challenges. He can be reached at

paul@perennialsolutions.com.