11/1/2017

Ensuring Beneficial Compatibility

Nancy Rechcigl

As new pest control options are introduced into the ornamental market, Integrated Pest Management (IPM) programs are becoming more comprehensive and diverse. By coordinating cultural, biological and chemical tactics, growers can better maintain or reduce pest populations to acceptable levels.

A successful IPM program is well thought-out, preventive and customized. It takes into account the crop being grown, common pests/diseases the crop may develop and provides a rotation strategy to minimize the likelihood of resistance. Gathering information before, during and after a program is essential to perfecting the strategy and achieving continued success, year-after-year.

To begin an IPM program, it’s important to evaluate preventive cultural practices, gather information from crop monitoring and examine environmental conditions. Growers should compile historical data on pests, diseases and resistance issues, as well as chemicals, biological control agents (BCAs) and other treatments used in the growing area to ensure compatibility. All IPM programs, including BCAs, are best used preventively, so understanding your crop and potential pest pressure is imperative.

Elements of a successful IPM program

- Scouting

- Monitoring

- Good record keeping

- Communication at all levels

- Preventive cultural practices

- Compatible chemicals and BCAs

Since ornamental pest activity doesn’t follow a calendar, the key to any successful IPM program is scouting. Below are some important scouting tips to help avoid the need for last minute rescue treatments:

- Start clean and stay clean by thoroughly inspecting all incoming plant material.

- Utilize sticky cards to monitor flying insect pests. Weekly evaluations should be done to monitor adult populations and help determine appropriate application and timing of control options.

- Look for obvious signs of plant damage, such as chlorotic, stunted or malformed growth, cast-off skins, feeding damage, honeydew, sooty mold and the presence of ants.

- Check undersides of leaves using a hand lens to detect infestations.

- Choose an insecticide or BCA that’s effective for the pest life stage present. Use scouting information to determine whether you’re above or below your action threshold to make effective pest control decisions.

Production facilities that don’t utilize a scouting program often rely on broad-spectrum calendar sprays and/or “curative” applications to gain control of established pest populations. Calendar spraying can result in unnecessary pesticide applications, may accelerate the development of resistance and are often not successful.

Importance of compatibility

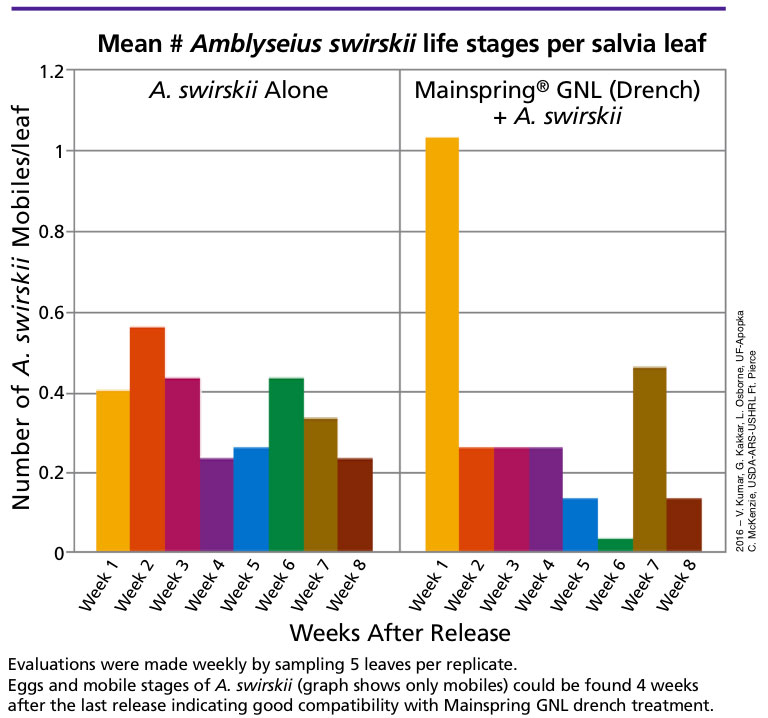

Knowing how traditional chemical products interact within an IPM program is critical to ensure compatibility between insecticides and BCAs. Research trials showing BCA compatibility have been completed for Mainspring GNL insecticide, which is powered by a novel active ingredient in a unique, non-neonicotinoid chemistry class (IRAC Group 28). These trials from the University of Florida—Apopka and the USDA-ARS Lab in Ft. Pierce, Florida, demonstrate that Mainspring GNL is compatible with Amblyseius swirskii and that the combination worked effectively to prevent whiteflies on ornamental crops.

Mainspring GNL has also shown compatibility with other beneficial insects, including Amblyseius cucumeris, Eretmocerus eremicus, Orius spp., Phytoseiulus persimilis and Hypoaspis miles.

Knowing that your insecticide and BCAs will work in tandem to control insect pests can save time, labor and resources. Keep up-to-date on compatibility research to ensure the products you choose are the right fit for your program.

A novel option

Incorporating products with a unique mode of action is another important component of an IPM program to help prevent the development of resistance. Growers should rotate chemistries in different classes, not just within the same IRAC group.

For example, products in IRAC Group 4D—the butenolides—shouldn’t be rotated with products in IRAC Group 4A—the neonicotinoids—because their modes of action are too similar and cross resistance can occur. Incorporating unique modes of action, like Mainspring GNL in IRAC Group 28, will help preserve available pest control options, especially those that can be used with other chemicals and with BCAs. It’s essential to avoid relying on one type of chemistry.

Cyantraniliprole, the active ingredient of Mainspring GNL, falls under the diamides class of chemistry. This mode of action activates ryanodine receptors, resulting in unregulated calcium release. When calcium stores are depleted in insect pests, it results in muscle paralysis and the pest loses the ability to continue feeding. Mortality then occurs within a few days.

Challenged by multiple pests

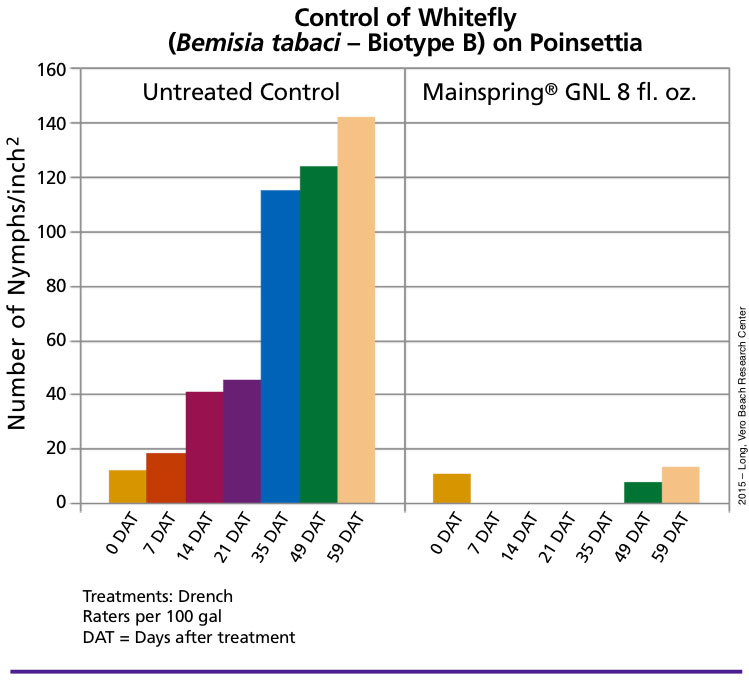

It’s not often that a grower only faces one insect pest throughout the season. With the right components and strategy, you can prevent multiple pests that might affect your crops. An insecticide with proven performance on a broad spectrum of insects can be a vital addition to an IPM program. Mainspring GNL controls key chewing and sucking pests, including aphids, whiteflies, thrips, leaf-feeding beetles (adult and larval stages), caterpillars, soft scales, lace bugs and more.

Whiteflies in particular have become increasingly common and damaging in the ornamental industry, especially biotype Q. In the battle against whitefly, as with most insect pests, scouting and treating preventively is essential for a successful crop. Resistance can be a big problem with whiteflies as well, so rotating chemistries and utilizing other means of control, like BCAs, are more important than ever.

In 2016, there were multiple outbreaks reported of Bemisia whitefly, specifically biotype Q. With a different genetic makeup than other species, growers had to find alternative solutions if the insecticides they were using didn’t control biotype Q.

Lance Osborne, professor of entomology at the University of Florida’s Mid-Florida Research & Education Center, recommends careful scouting when it comes to whitefly control and found Mainspring GNL to be an effective option based on his trials.

“When it comes to controlling whitefly, including the Q biotype, growers are shipping product into environments that are unfriendly to the use of neonicotinoids and they need an alternative that is effective,” Dr. Osborne says. “Now we have the potential of a chemical compound that can be used that’s beneficial-friendly and pollinator-friendly, and it’s a non-neonicotinoid.”

Stick with it

Implementing an IPM program takes time and patience. Early detection by scouting will allow growers to substitute or incorporate a targeted insecticide or BCA application before pest populations reach unmanageable levels. This will also help decrease the likelihood that pests will develop resistance. Be sure to research both the chemicals and BCAs in your program to ensure compatibility and avoid trial and error.

With newer, innovative chemistries available, growers have more products in their arsenal to combat insect pests and diseases in the greenhouse and nursery. Mainspring GNL is available for growers in combination packs with Avid 0.15EC miticide/insecticide or Mural fungicide, another recent introduction to the ornamental market that provides broad-spectrum disease control. GT

For more information, visit GreenCastOnline.com/MainspringGNL.

Nancy Rechcigl is the field technical managerfor ornamentals at Syngenta.