3/1/2018

Managing Your Lighting

Bill Swanekamp

As we press through the dark days of winter, we look forward to the days getting longer and longer. Pretty soon we’ll pass the equinox and watch the plants explode in growth as if they were on steroids.

In the meantime, we still have to get through the worst of the winter. For many young plant producers, using artificial lighting is essential. Without these HID lights, we wouldn’t be able to produce a plug or rooted cutting in a reasonable time during the winter. In fact, in some cases, the plants would barely grow at all.

About 25 years ago, we invested in our first HID lights. They were 440 W sodium vapor lights and put out an incredible amount of light. We used to joke that we needed to wear sunglasses in the greenhouse at night. Today, some of those same fixtures are in the greenhouse.

Over the years, when an HID bulb burned out, we would replace the bulb or ballast, whichever was needed. This was done numerous times through the growing season to be sure all the lights were working. Recently, it occurred to me that maybe just observing whether a lamp was on or off wasn’t enough. So we decided to map all the HID lights in the greenhouse and measure each fixture’s light output.

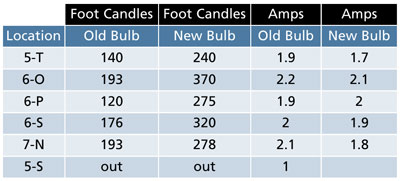

Each measurement was done in foot candles and taken a fixed distance from each lamp so that the results would be consistent. The first set of measurements were taken about 36 in. from the HID bulbs and each light’s output was noted in a spreadsheet. It’s important to take the light measurement the same distance from each bulb to get consistent results bulb to bulb. Remember that light output is an inverse to the distance from the source, so light level drops considerably as you increase the distance. For example, the light level 6 in. from one bulb was 925 f.c. and 400 f.c. 12 in. away from the same bulb. Another bulb was 1,400 f.c. 6 in. from the bulb and 450 f.c. 12 in. from the bulb.

Now that we had some data, we started to compare one light’s output to another. We found that our highest light level 36 in. from the bulb was 500 f.c. and our lowest level was 40 f.c. This was a 12-fold reduction in output. Next, we looked at all the bulbs light output and found that about one-third of the lamps were putting out much less light than we expected—in many cases, about half of the light we expected. This in itself is alarming because the starter plants aren’t getting the amount of light we felt they needed to get a good start. Of course, if we have a sunny winter, the reduction in light from the lamps isn’t as significant. But if we have a dark, cloudy winter, this reduced light will be significant.

Now we wanted to find the answer to the $64 q uestion! If the light output of a fixture goes down, does the electrical consumption go down as well? After setting up another test, where we measured the light output of a weak bulb, then measured the amperage drawn by that light, replaced the old bulb with a new one and then measured the amperage draw, guess what we learned? The amount of energy used by an old, poor output bulb is virtually the same as a brand-new bulb (see the chart).

uestion! If the light output of a fixture goes down, does the electrical consumption go down as well? After setting up another test, where we measured the light output of a weak bulb, then measured the amperage drawn by that light, replaced the old bulb with a new one and then measured the amperage draw, guess what we learned? The amount of energy used by an old, poor output bulb is virtually the same as a brand-new bulb (see the chart).

This course is very disconcerting. There’s no reduction in amps with an old bulb compared to a new bulb. In fact, in most cases, the new bulb used slightly less electricity. But if you look carefully at the chart, the bulb marked 5-S isn’t even lit and is using one amp of electricity. No light at all is coming out of the fixture, but it’s still using 50% of the energy of a new, bright bulb. Scary!

What’s the lesson? Set up a regular maintenance schedule for your lighting fixtures and create a recording template that allows you to easily track the amount of light output from each bulb and change the bulbs as the output goes down. That way, your plants will get the maximum benefit from your precious artificial lights. GT

Bill Swanekamp is president of Kube-Pak Corp., Allentown, New Jersey.