11/1/2017

Bringing Their Passions to Life

Anne-Marie Hardie

Growing up, co-founder of Little Leaf Farms, Larissa Nicholson, had always felt a strong connection to nature.

During high school, Larissa worked as a florist and then in landscape maintenance, where she discovered she wanted to learn more about growing. This resulted in Larissa pursing an education in Horticulture at Niagara College.

Her fiancée and co-founder, Jon Hassel, followed a similar path, working in landscape maintenance during high school and then pursuing a Niagara College degree in Landscaping.

“I think Jon and I both believe that we aren’t separate from nature, but a part of it,” explained Larissa. “We’ve always wanted to work with plants, and over the years, have become extremely interested in permaculture.”

After graduating, Jon and Larissa worked for Stouffville’s Green Belt Greenhouse growing microgreens. It was here they gained both the knowledge and inspiration to pursue opening their own business in this growing sector of horticulture.

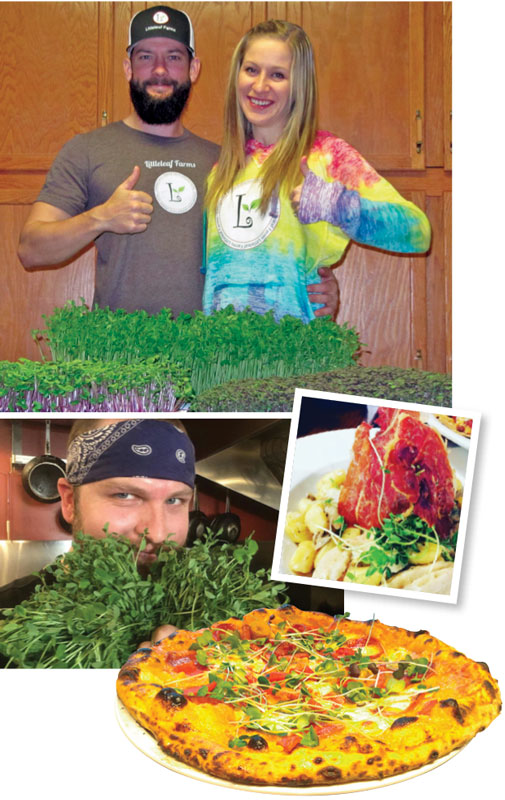

Pictured clockwise from top: Larissa Nicholson and her fiancée Jon Hassel own Little Leaf Farms, a microgreens-growing business that caters to local restaurants in the Cavan, Ontario, area. • Microgreens from Little Leaf Farms on a dish at Ashburnham Ale House. • Their microgreens on a pizza at Publican House. • Ashburnham Ale House Chef Chad Kemp loves the pea tendrils microgreens from Little Leaf Farms.

“We wanted to produce a local food that was both highly nutritious and profitable,” said Larissa. With the ability to turn crops every two to three weeks, microgreens were exactly the type of opportunity the couple was looking for.

With their future at top of mind, the couple moved to a home in Cavan, Ontario, and began saving their money and researching potential competitors.

“There was no other company in the area doing microgreens and so we started a period of nine-month trials in our 1,200-sq. ft. basement, experimenting with different mediums and harvest times,” said Larissa. A microgreen called Popcorn, for example, changed substantially in taste in only two to three days. The results from the trials equipped Little Leaf Farms with a best practice guideline for harvesting, which included opting for organic soil for their growing medium.

With both the harvesting time and medium confirmed, Larissa and Jon launched their microgreen business. During the initial month, Jon invested his time sowing and growing the microgreens, while Larissa reached out to local restaurants, inviting them to try their samples.

“The first restaurant we went to connected us to two other restaurants,” said Larissa. “It’s amazing how everyone in this area is connected.”

Having a horticulture background provided them with a strong advantage, shared Larissa, as they could apply their course knowledge—including honed research skills—to develop stronger, healthier crops. But that’s not all … the chefs, who are their primary clients, felt comfort in knowing their produce was being grown by individuals who understood the industry.

“The chefs are astounded that our microgreens can last up to about three weeks,” said Larissa. “But I believe that this is directly related to the way we grow and harvest our microgreens.”

Although not certified organic, as this can take up to three years to achieve, Little Leaf Farms sources only organic, non-GMO seeds and uses solely organic methods to grow and manage their produce. Seaweed kelp is diluted in the water to help enhance both the color and flavor of the microgreens.

Little Leaf Farms has also invested in an ozone water treatment system for sterilization, eliminating 99% of the pathogens. As an added benefit, the additional oxygen in the water helps to grow a stronger root system.

“Using the oxygenated water helps to extend the plant’s longevity,” said Larissa. “I firmly believe that it is both the quality of our water, and how we water, that makes the biggest difference in our plants.”

Jon waters every plant with a watering can using the bottom up method. This method helps to prevent overwatering, while also reducing the risk of mold, by keeping the leaves of the plants dry.

With chefs as their primary customer, Little Leaf Farms has adopted a grow-to-order business model. Upon signing, the chefs specify both the type and number of microgreens for their weekly order, and then Little Leaf Farms adjusts the amount of seeds that they sow to accommodate for the new business. Essentially, this means that the initial order may take a few weeks to receive, but after that, the chefs will receive their specified order every week. Having this consistent weekly order helps Little Leaf Farms forecast the amount of microgreens that’ll need to be grown and

harvested.

Currently, they’re growing 22 varieties of microgreens, including the recent addition of basil, cilantro, shisso, rainbow Swiss chard and wasabi mustard—crops that were specifically requested from the chefs.

“Chefs are our customers; they are our main source of business and we want to make sure that we respond to their needs,” said Larissa.

Five months into their new business, and with 15 restaurant clients on board, Larissa and Jon are committed to taking their business to the next level.

“A lot of people have asked us to do edible flowers and so we agreed to do some trial runs,” said Larissa. “Our hope is that we will be able to fulfill the orders in time for the holiday season.”

For the moment, they’re trying to run the business with just the two of them, with the intent of allocating the additional revenue to future growth.

“The numbers are looking really good, with the profits increasing each month that we’ve been in business,” said Larissa.

Currently, they’re investigating growing their produce in shipping containers, with plans to eventually have one dedicated for microgreens and the other for edible flowers.

“However, the most affordable price that we found is $50,000,” said Larissa. “And so we are looking at whether we can create the shipping container

ourselves.”

With sustainability at top of mind, they would eventually like to add solar panels to take some of their energy use off the grid and integrate a rain catchment system for their watering.

“Down the road, when our budget allows, we would like to see if we could do some permaculture consulting to help turn people’s yards into gardens, working with permaculture techniques,” said Larissa.

For the immediate future, Larissa and Jon are excited about exploring the edible flower side to the restaurant industry and learning about this potential growth opportunity. At the same time, they’re thrilled to be growing their own family, with a new little one on the way. GT

Anne-Marie Hardie is a freelance writer/speaker from Barrie, Ontario, and part of the third generation of the family-owned garden center/wholesale business Bradford Greenhouses in Barrie/Bradford, Ontario.